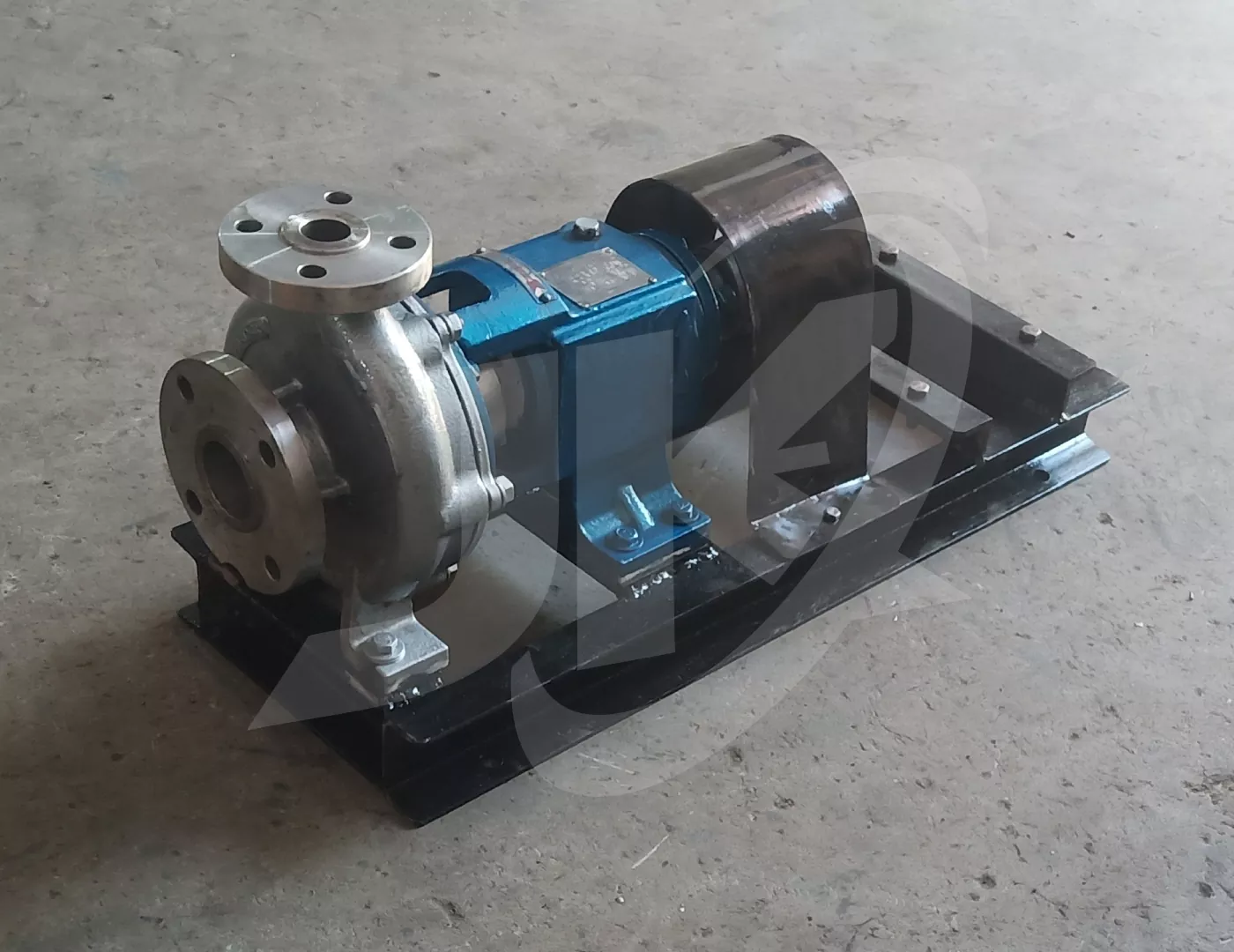

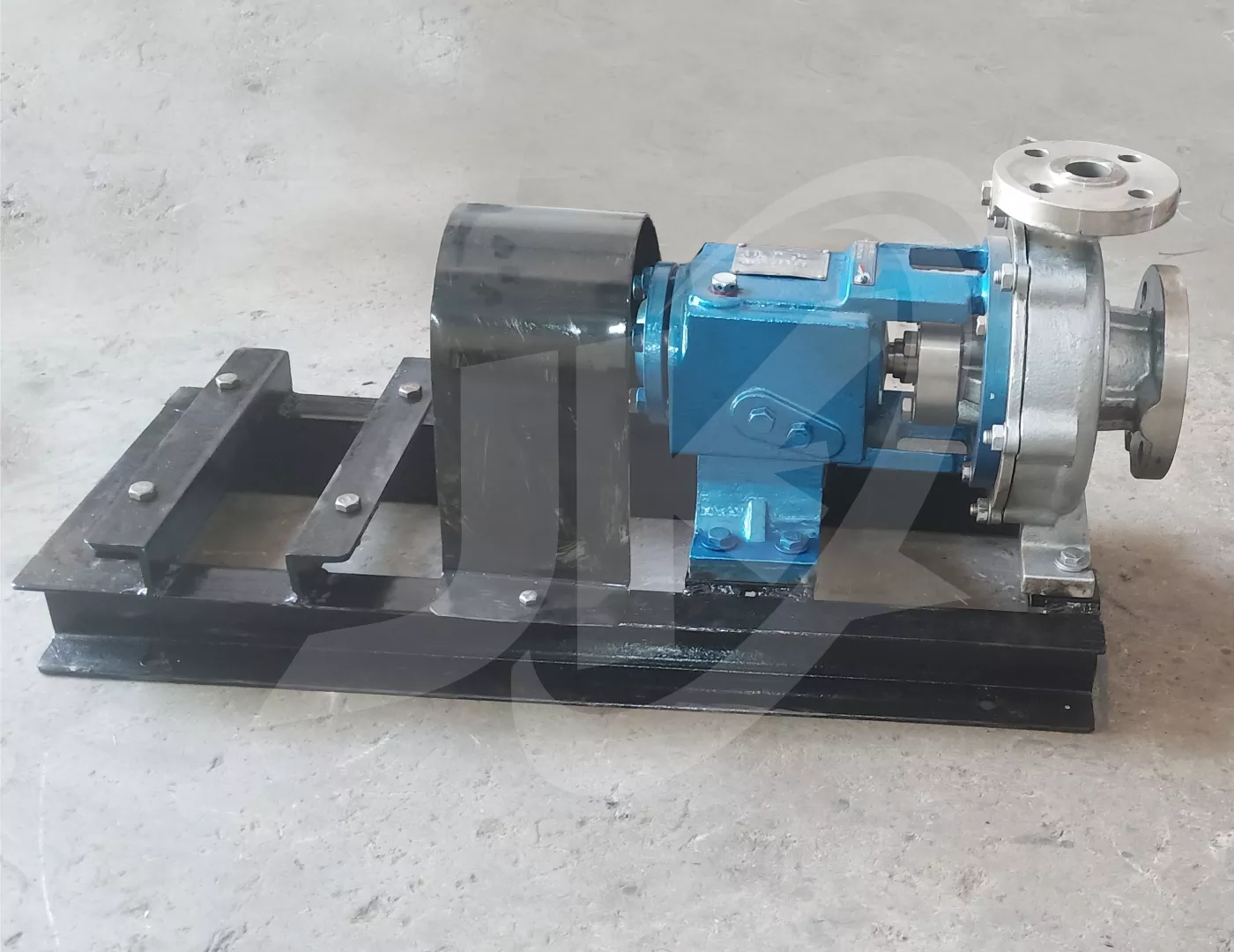

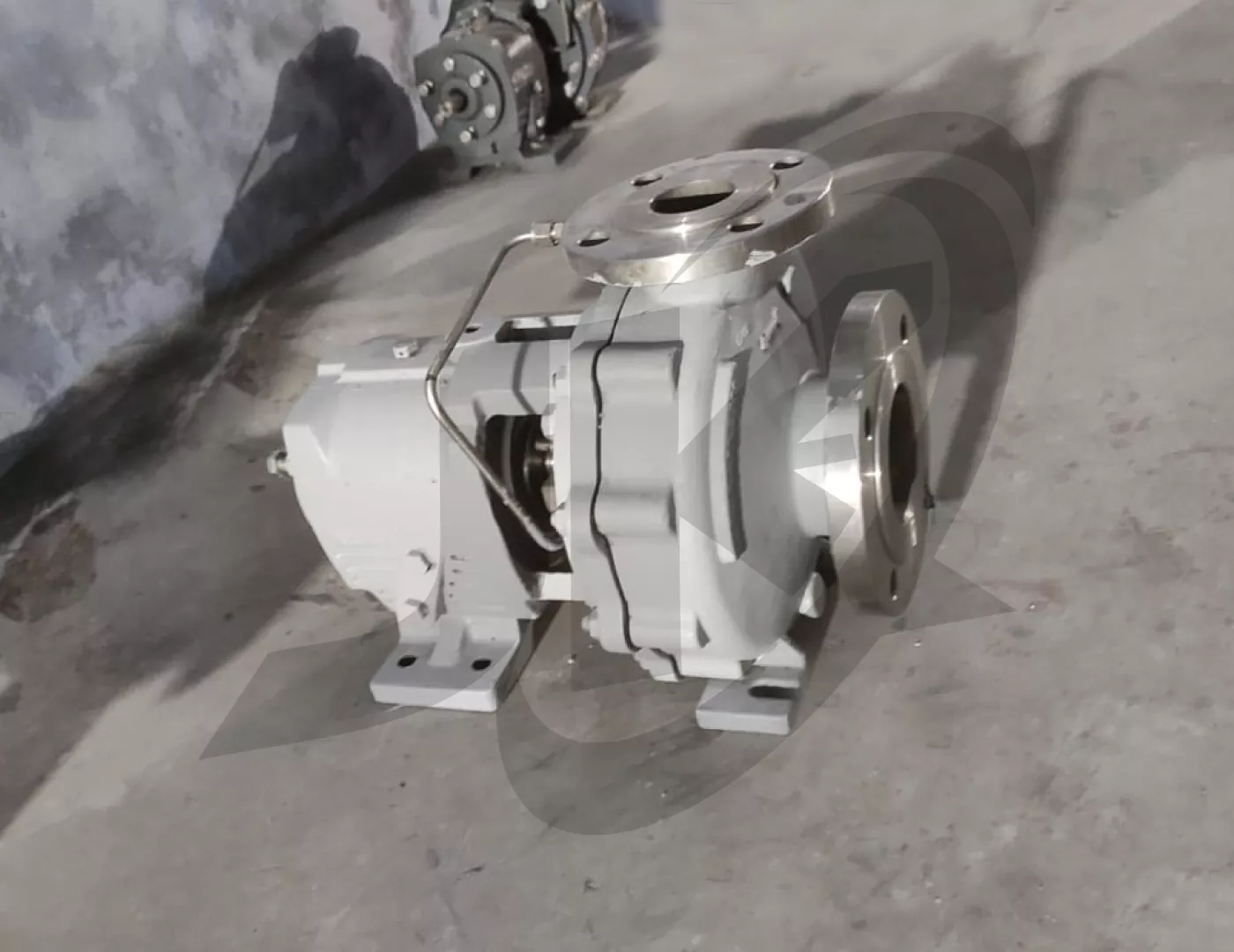

Semi-Open Centrifugal Pump Manufacturer in India

(JKSCP SERIES)

Centrifugal Coupled Pump with Semi-Open Impeller is designed for optimum performance using the best quality raw materials and the latest technology. Jay Khodiyar Engineering Works is one of the most widely recognized industrial pump manufacturers and suppliers in Ahmedabad.

We offer a quality range of customizable Semi-Open Centrifugal pumps highly appreciated for their rugged construction, advanced mechanical design, best pumping performance, and many other unique features.

Our Semi-Open Centrifugal pumps are fully compliant with the latest industry standards and well-suited for wide industrial applications.

As a trusted Semi-Open Centrifugal Pump manufacturer, we deliver innovative pumping solutions for diverse industries, ensuring precision, durability, and peak performance.

- Maximum Interchangeability

- Greater Quality Control and Accuracy

- Back Pull–Out Design

- Exclusive Balanced Thrust

- Fully Open Impeller With Back Pumps

- Low Maintenance

Constant dimensions that apply to Jay Khodiyar Engineering Works type – JKSCP, Standardized Chemical Pumps.

| Capacity | Upto 800 m3/hr |

|---|---|

| Head | Upto 150 Meter |

| Temperature | 300 C Max |

| Speed | Upto 3600 rpm |

| MOC | C.I Cast Steel (Wcb), S.S 304, S.S 316 |

Download Our Semi-Open Centrifugal Pump Catalogue

Applications of Semi-Open Centrifugal Pump

ETP, STP wastewater treatment plant

Fertilisers, Cement, and Steel Industries

Pumping Chemicals

Paper and Pulp Industries

Organic / Inorganic Chemicals

Volatile Liquids

Corrosive Chemicals

Caustic Process

Effluent

Filter Press

Slurry Application

Pharmaceutical

Dyes

Textiles

Kerosene

Diesel and other Solvents

Find the Ideal Pump Solutions Tailored to Your Needs Right Here!

Why Choose Our Industrial Pumps?

Benefits of Our Semi-Open Centrifugal Pump

- High Efficiency: Often more energy efficient than other types of pumps

- Reduced Clogging: Minimizes blockages and allows larger particles to pass

- Versatility: Handles a wide range of liquids, including those with solids and offers a balanced performance

- Easy Maintenance: Simple access to the impeller for cleaning and repairing

- Robust Construction: Designed with durable materials to operate in harsh conditions

Customization options in Semi-Open Centrifugal Pump

We do Offer customization options for specific client requirements, including materials, sizes, flow capacities, and pressure ratings.