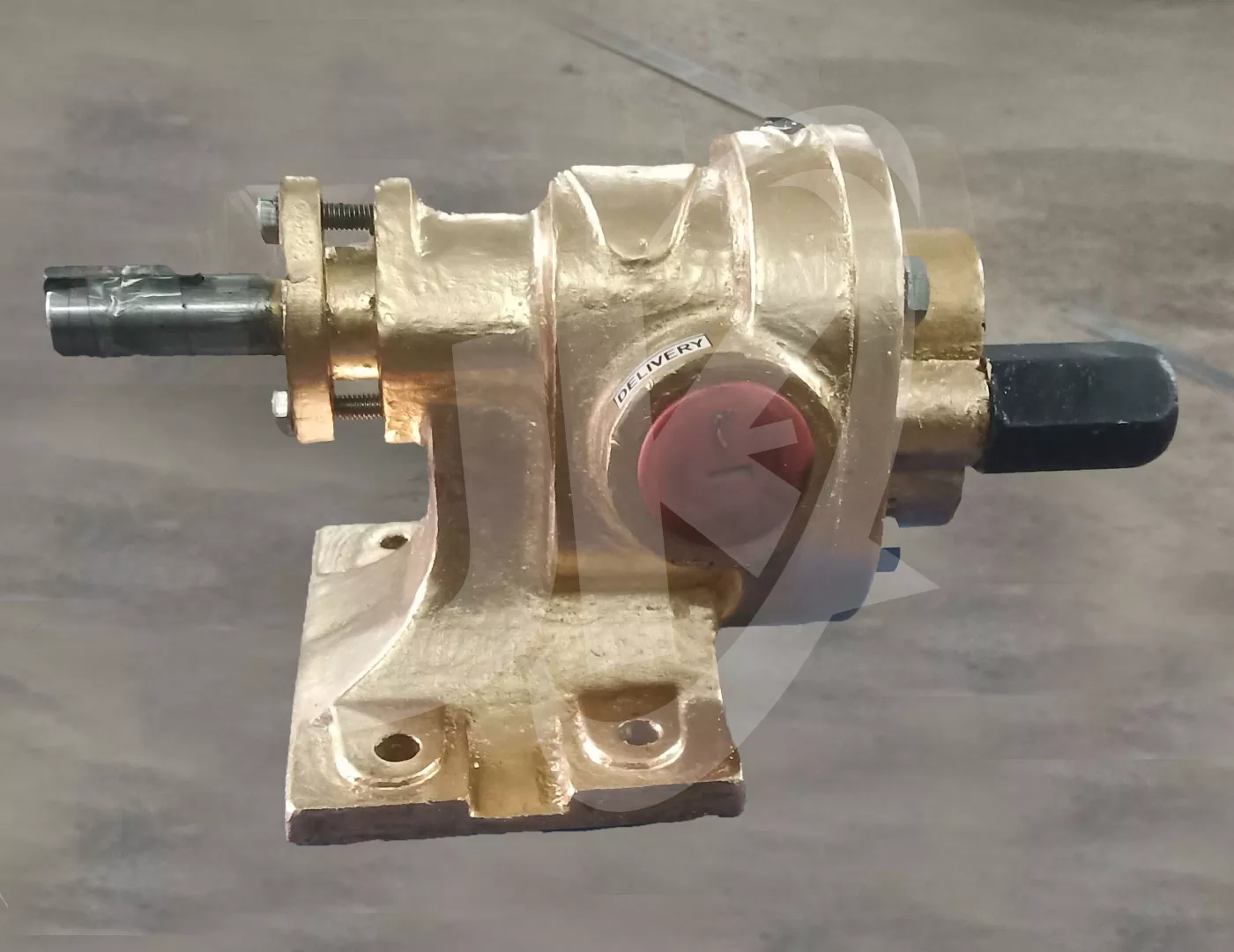

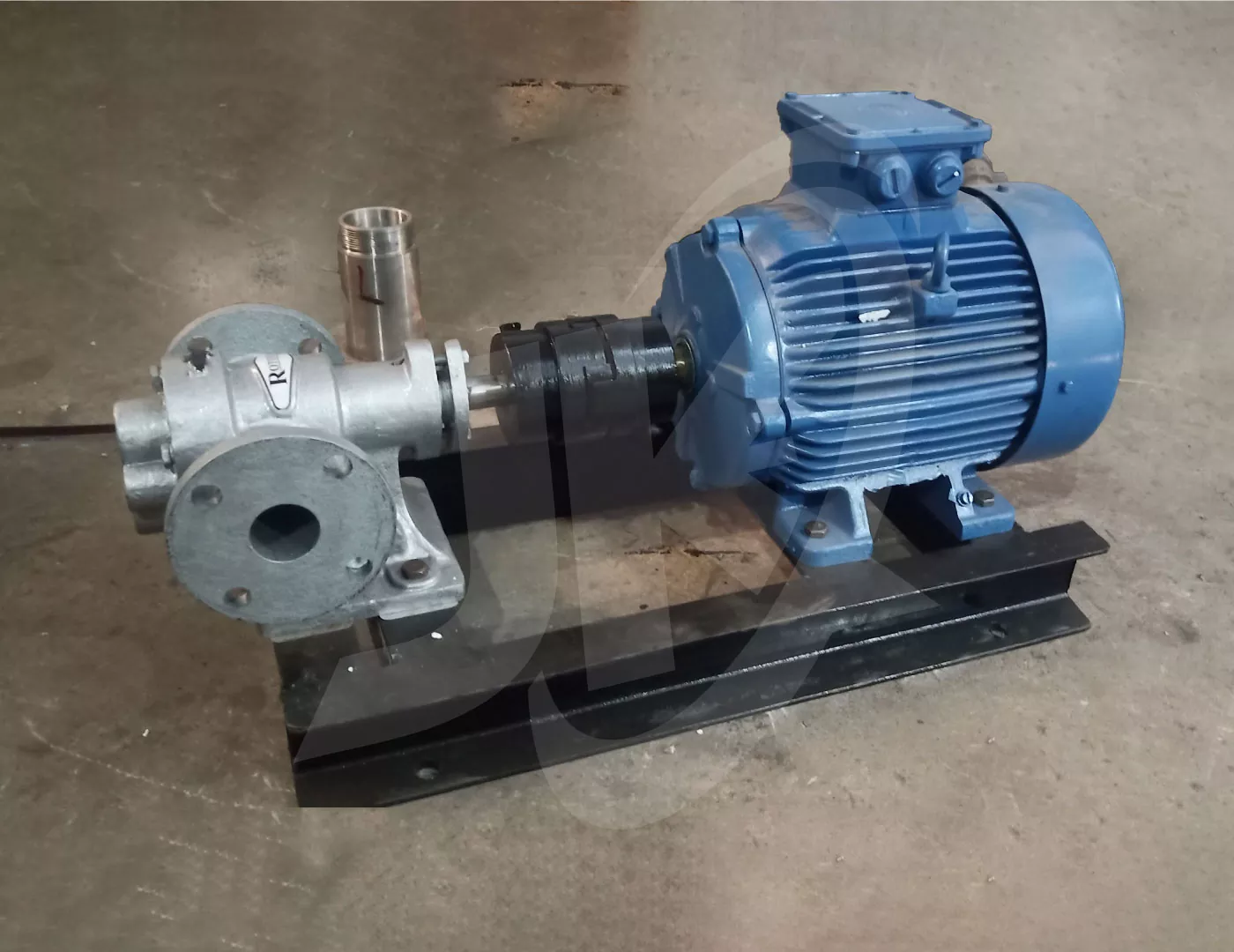

Rotary Gear Pump Manufacturer in India (RT SERIES)

Jay Khodiyar Engineering Works is a renowned Gear Pump manufacturer in India, supplying a wide range of Rotary Gear pumps. Widely recognized for their quality and efficiency, our Rotary Gear pumps are highly reliable, with exceptional resistance to wear and corrosion making them well-suited for the most demanding industrial applications.

Durable and reliable, designed as per industry stringent specifications, these gear pumps are highly appreciated; due to their unique features and quality performance at the most affordable price.

As a trusted Rotary Gear Pump manufacturer, we deliver innovative pumping solutions for diverse industries, ensuring precision, durability, and peak performance.

- Compact Size

- Low Noise

- High Efficiency

- Easy To Maintain

- Low-Cost

- Rugged Design

- Highly Durable

- Long Service Life

Download Our Rotary Gear Pump Catalogue

Applications Of Rotary Gear Pump

Rotary Gear Pumps are useful for handling viscous liquids & viscous chemicals in various industries like Food, Power Plants, Steel Mills, Refineries, Oil Storage installations, etc. Below are the following liquids that can be handled with them.

- All Kind Of Mineral Oils

- Coal Tar, Bitumen, Asphalts

- All Kind Of Fish & Animal Oils

- Glue

- Organic/Inorganic Chemical

- All Kind Of Vegetable Oils

- Paints & Varnish

- Glycerine & Glycole

- Viscous Chemicals

- Volatile Liquids

Want to Match the Need of High-demanding Industrial Applications?

Why Choose Our Industrial Pumps?

Benefits of Our Rotary Gear Pump

- Consistent Flow: Provides smooth, pulsation-free flow.

- Self-Priming: Can handle air and gas pockets.

- Durable: Reliable, even under harsh conditions.

- Compact: Ideal for tight spaces.

- Low Maintenance: Fewer moving parts reduce downtime.

- Versatile: Handles various fluids, including viscous and corrosive ones.

- Efficient: Minimizes energy loss and operating costs.

- High Pressure: Capable of generating substantial pressure.

- Excellent Suction: Strong suction capabilities.

- Adjustable Flow: Flow rate can be easily controlled.

- Leakproof: Minimizes fluid loss and contamination.

- Low Noise: Quiet operation for sensitive environments.

Customization options in Rotary Gear Pump?

We do Offer customization options for specific client requirements, including materials, sizes, flow capacities, and pressure ratings.

What is a Rotary Gear Pump?

A rotary gear pump is a type of positive displacement pump that uses two interlocking gears and cogs to create suction and force fluid through a pipe or system. These pumps are widely used in various industrial and commercial applications due to their simple design, reliability, and ability to handle a wide range of fluid in a fixed volume.

How Does Rotary Gear Pump Work?

- The gears are mounted on shafts that are turned by an external motor. As the gears rotate, they create spaces between their teeth.

- Fluid is drawn into the pump through the inlet port. The spaces between the teeth act as chambers, trapping the fluid.

- As the gears continue to rotate, the trapped fluid is carried around the pump housing.

- The fluid is then discharged from the pump through the outlet port.

Types of Rotary Gear Pump

External Gear Pumps

Simple and robust, good for clean fluids, low to medium viscosity, and pulsating flow.

Internal Gear Pumps

High efficiency, smooth flow, good for high viscosity, slurries, and sensitive liquids.

Lobe Gear Pumps

Handle larger particles, higher viscosity, high sanitary standards, and pulsating flow.

Multiple Gear Pumps

High flow rates and pressure, heavy-duty applications, and complex design.