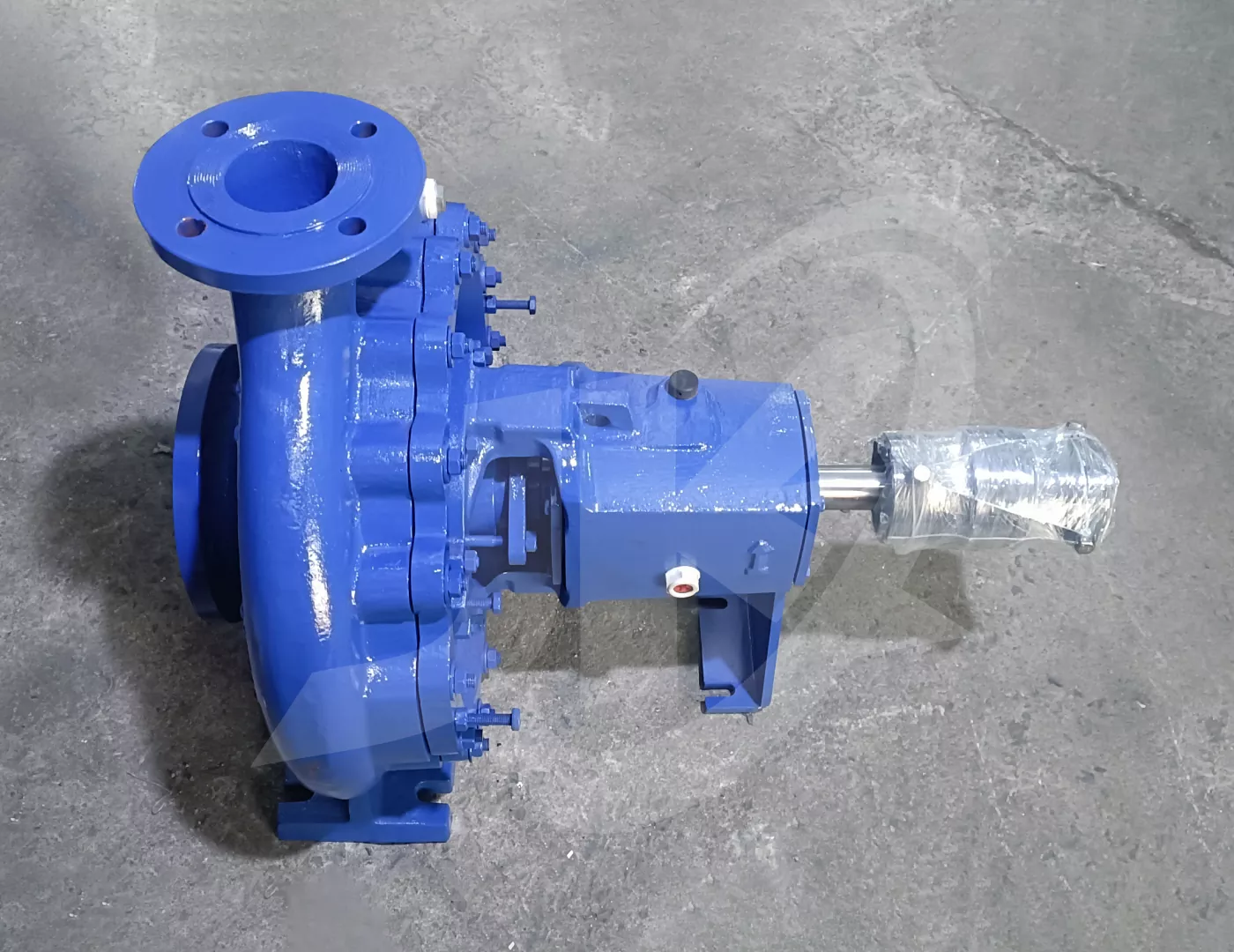

Closed Impeller Centrifugal Pump Manufacturer in India (JKCIP SERIES)

Being the leading industrial pump manufacturer, Jay Khodhiyar Engineering Works offers high-performing centrifugal pumps to withstand a variety of mechanically aggressive and high-temperature liquids.

Our JKCIP series pumps are an advanced design Closed Impeller Centrifugal Pump manufactured for tackling all kinds of liquids in chemical industries. With superior casting qualities, intrinsic designs, and hydraulics, our centrifugal pumps are ideal for your chemical industry.

These pump dimensions are designed as per ISO 28588 Pump Standard and ISO 5199 as the Pump Testing Standards making them more efficient pumps and much better in terms of Hydraulics.

- Maintenance Free

- Superior Casting Qualities

- Better Bearing Life

- Highly Efficient

- Chemical & Corrosion Resistant

| Capacity | 500M3 / hr |

|---|---|

| Head | 160mtrs |

| Size | 25 to 150 |

| Speed | 1400 to 2800 |

| Temperature | 160 |

| M.O.C. | C.I, WCB. S.S 304, S.S 316/316L Alloy-20, CD4MCU Etc |

Download Closed Impeller Centrifugal Pump Catalog

Need a Pumping Solution Enclosed with Efficiency?

Applications

Chemical And Petrochemical

Sugar And Alcohol Industry

Boiler Feed

Circuits In Refineries & Industries

Water Supply

Irrigation

Air Conditioning

Fire-Fighting

Drainage

Circulation Of Heat Transfer Oil

Find the Ideal Pump Solutions Tailored to Your Needs Right Here!

What is a Closed Impeller Centrifugal Pump?

A closed impeller centrifugal pump is a type of centrifugal pump that has vanes at both front and back to provide maximum strength. This enclosed impeller decreases the thrust load on the shaft while offering longer bearer life, reduced shafting costs, and improved reliability.

How Does Closed Impeller Centrifugal Pump Work?

- The blades spin at high speed in a circular motion to increase pressure and velocity for fluids.

- The impeller creates a negative pressure in the center of an impeller which draws liquid into the impeller.

- The contributed centrifugal force by the impeller on the liquid throws the liquid outwards radially.

Advantages of Closed Impeller Centrifugal Pump

- Increased Bearing Life

- More Efficiency

- Reduced Thurst Load

- Reduced Shafting Costs

- Low Maintenance