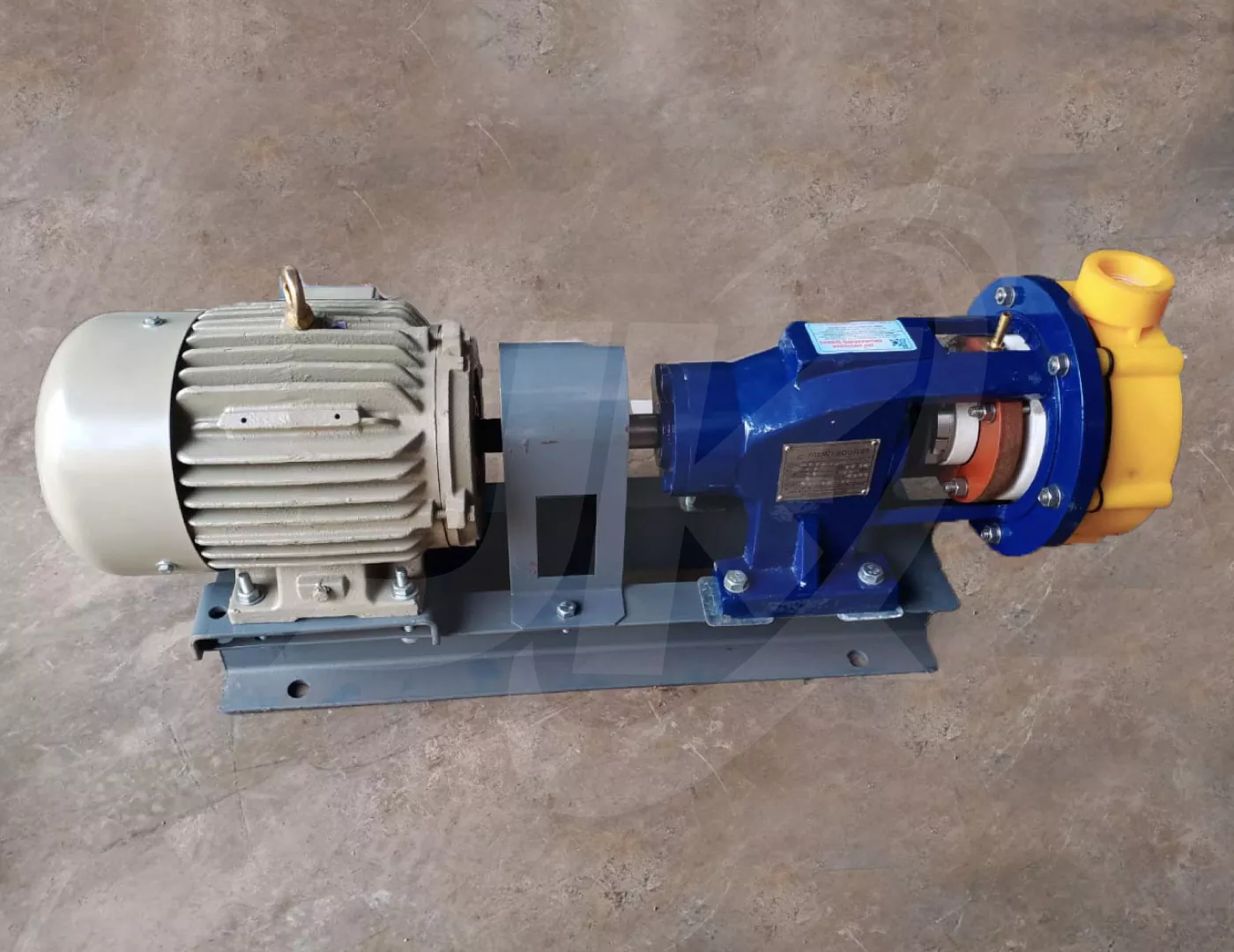

Centrifugal Polypropylene Pump Manufacturer In India

Centrifugal Polypropylene Pumps are the preferred choice for various industries due to their trouble-free performance against erosion.

Jay Khodiyar Engineering Works is one of the prominent industrial pump manufacturers and suppliers delivering the best quality Centrifugal Polypropylene Pumps to deal with highly corrosive chemicals.

Our pumps are designed to deliver exceptional performance, durability, and reliability in the harshest of environments. With deep industry knowledge and manufacturing expertise, we offer customized pump solutions at the most competitive market prices.

As a trusted Centrifugal Polypropylene Pump manufacturer, we deliver innovative pumping solutions for diverse industries, ensuring precision, durability, and peak performance.

- Easy Maintenance

- Strong Construction

- Leak Proof

- Efficient Design

- Corrosion Resistant

| Capacity | up to 280 m³/h/ hr |

|---|---|

| Head | up to 60 m / hr |

| Operating Temperature | -20°C up to +110 °C |

Download Our Centrifugal Polypropylene Pump Catalogue

Applications Of Centrifugal Polypropylene Pump

- Chemical Industry

- Metallurgical Industries

- Evaporation And Regeneration Units

- Exhaust Air Scrubbing

- Electroplating Plants

- Steel And Stainless Steel Pickling Lines

- Wet Flue Gas Cleaning Systems

- Industrial Wastewater Treatment

Want to Power Up the Polypropylene Pump

Why Choose Our Industrial Pumps?

Benefits of Our Centrifugal Polypropylene Pump

- Corrosion Resistance: Ideal for handling aggressive chemicals, acids, and alkalis.

- Durability: Long-lasting even in harsh conditions.

- Lightweight: Easier to handle and install.

- Cost-Effective: Affordable compared to metal pumps.

- High Efficiency: Reliable performance with energy savings.

- Abrasive Resistance: Suitable for slurries and fluids with solids.

- Non-Toxic: Safe for food and pharmaceutical use.

- Low Maintenance: Simple design and fewer moving parts.

- Customizable: Adaptable to specific needs.

Customization options in Centrifugal Polypropylene Pump

We do Offer customization options for specific client requirements, including materials, sizes, flow capacities, and pressure ratings.

What is a Centrifugal Polypropylene Pump?

Centrifugal polypropylene pumps are chemical pumps made of thermoplastic polymer and designed to handle highly corrosive liquids, including acids, solvents, and harsh chemicals. These pumps are widely used in areas where metal is not an option and for extremely corrosive substances. These pumps are powerful and durable due to their resistance to erosion.

How Does a Centrifugal Polypropylene Pump Work?

- Centrifugal polypropylene pumps work by transferring rotational energy from one or more impellers to fluid.

- Fluid enters the inlet and travels towards the impeller shaft while rotating itself exponentially along with the impeller vanes.

- The impeller’s movement creates a vacuum in the suction pipe and atmospheric pressure pushes fluid into the pipe and the pump.

- The impeller sends fluid toward the sides of the pump casing and creates a centrifugal force that directs fluid toward the pump outlet.

Advantages of Centrifugal Polypropylene Pumps

- Highly Corrosion Resistant

- Higher Flow Rates

- 100% Leak-proof

- Compact Design