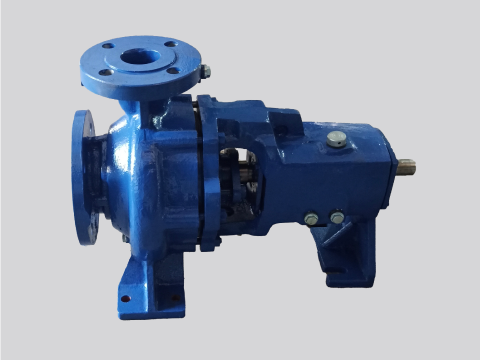

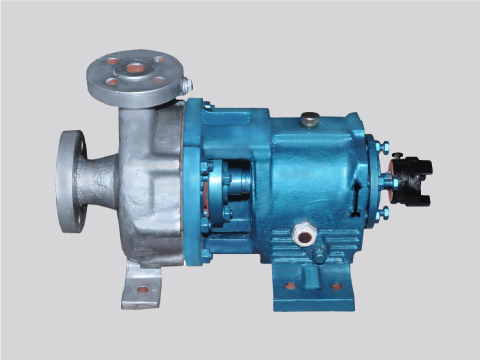

Centrifugal Pump Manufacturer In India

Jay Khodiyar Engineering Works is an internationally recognized centrifugal pump supplier in India. We have been manufacturing a high-quality and innovative range of centrifugal pumps for more than two decades.

Our range of centrifugal pumps is well-designed and constructed for smooth liquid flow in every application. From pumping water and solvents to oil and acids, our centrifugal pumps perfectly match the customer application requirements and are ideal for industrial, agricultural, and domestic uses.

With years of experience in offering the right and most efficient centrifugal pumps, we pride ourselves on being amongst the top 10 centrifugal pump manufacturers in India in the pump manufacturers list.

Need High-Performance Pumps?

We have the perfect solution for your industries

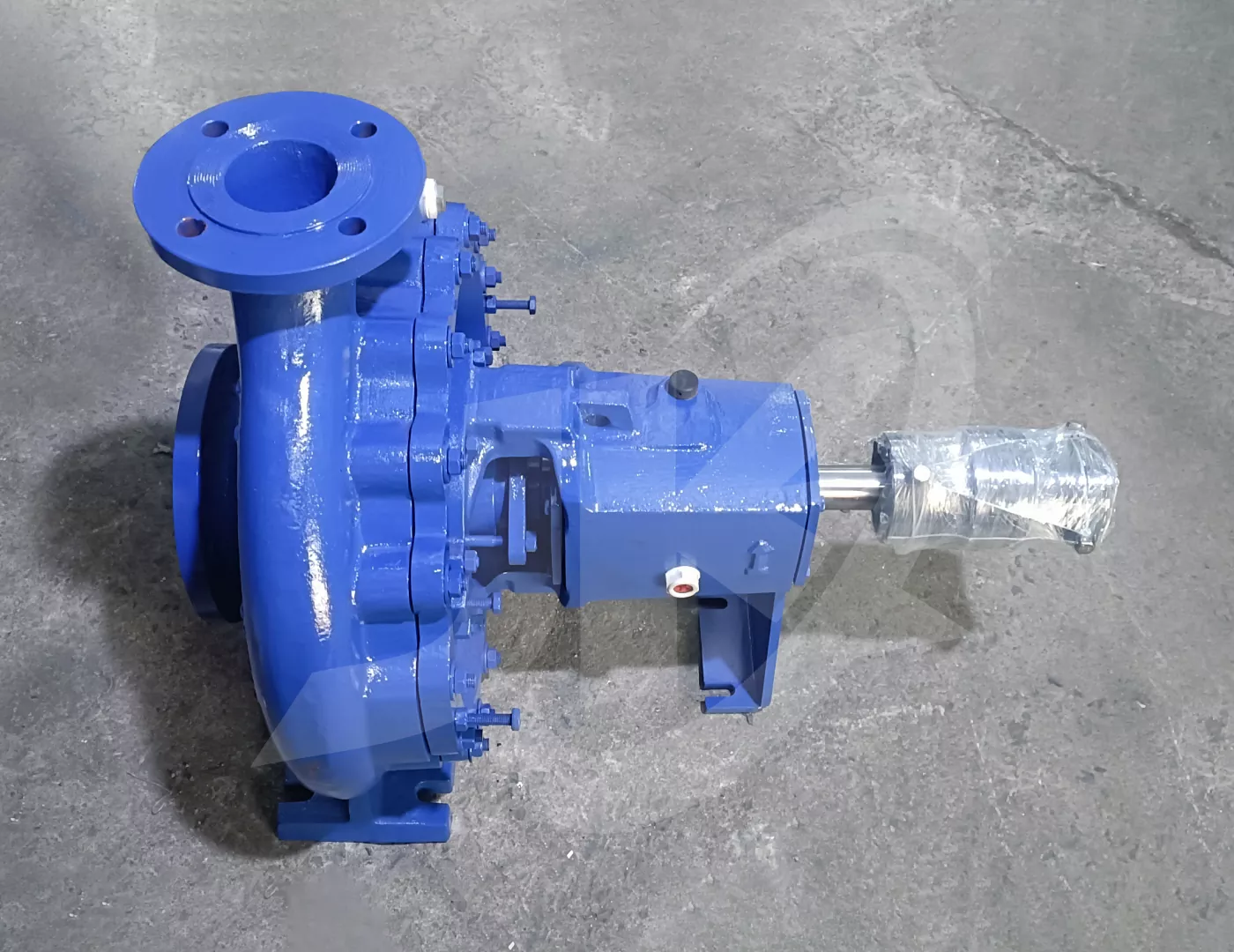

Centrifugal Pump Cross Sectional Drawing

- Highly Versatile

- Energy Efficient

- High Operating Reliability

- Safe Fluid Handling

- High Productivity

- Low Maintenance

- Heavy Duty Design

| Capacity | 500M3 / hr |

|---|---|

| Head | 160mtrs |

| Size | 25 to 150 |

| Speed | 1400 to 2800 |

| Temperature | 160 |

| M.O.C. | C.I, WCB. S.S 304, S.S 316/316L Alloy-20, CD4MCU Etc |

Types of Centrifugal Pump

Applications of Centrifugal Pump

Sugar Plants

Pharmaceutical

Chemical Industry

Seawater

Laminate Industry

Marine - Ports

Heat Exchanger

Food & Beverage

Textile Industry

Agricultural

Ceramic

Industry

Waste-water Treatment

Automobile Industry

Thermic Fluid Boiler

Oil & Gas

Industry

Want to Fill the Flow Requirements?

Why Choose Our Centrifugal Pumps?

Centrifugal Pump Videos

What is a Centrifugal Pump?

A centrifugal pump is a mechanical device that uses rotating impellers to move fluids by converting rotational kinetic energy to hydrodynamic energy. It's essentially a rotating machine that takes in liquid at its center and expels it outward at high pressure.

How Does Centrifugal Pump Work?

- The impeller rotates, and the blades fling the fluid outward due to centrifugal force.

- The fluid accelerates as it moves through the impeller and exits into the casing.

- The casing gradually increases in diameter, which converts the fluid's velocity into pressure.

- The fluid exits the pump through the outlet at a higher pressure than it entered.

Benefits of Our Centrifugal Pumps

- Cost-Effective: Lower initial and maintenance costs.

- High Efficiency: Efficient for a wide range of flow rates and pressures.

- Versatility: Can handle various liquids and applications.

- Smooth Operation: Provides steady, continuous flow with minimal pulsation.

- Easy Installation: Simple design allows for quick and flexible installation.

- Low Maintenance: Generally, requires less upkeep.

- Adaptable: Can be customized with different impeller designs for specific needs.

Customization options in Centrifugal Pumps

We do Offer customization options for specific client requirements, including materials, sizes, flow capacities, and pressure ratings.