Hot Oil Pumps for Thermal Fluid Heating Systems

June 24, 2025

5 Warning Signs Your Centrifugal Pump is About to Fail (And How to Fix Them)

July 26, 2025Introduction

Choosing the right centrifugal pump impeller type can make or break your industrial operation's efficiency and cost-effectiveness. The difference between semi-open and closed centrifugal pumps lies primarily in their impeller design, with each type offering unique advantages for specific applications. Understanding these differences is important for engineers, plant managers, and procurement professionals across the global manufacturing sector.

Semi-open and closed impeller designs represent two fundamental approaches to centrifugal pump construction, each optimized for different fluid handling challenges. While closed impellers excel in clean fluid applications requiring high efficiency, semi-open designs prove superior for handling slurries, abrasive materials, and fluids with suspended solids. This comprehensive guide explores both types to help you make informed decisions for your industrial pump needs.

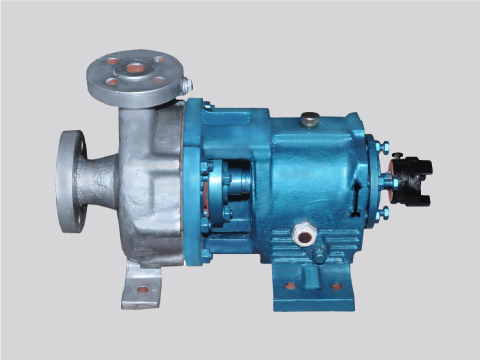

What is a Semi-Open Centrifugal Pump?

A semi-open centrifugal pump features an impeller design where the vanes are attached to a back shroud only, leaving the front side open. This configuration creates a less restrictive flow path that allows larger particles and debris to pass through without causing blockages. Semi-open impellers are specifically engineered to handle challenging fluids containing suspended solids, making them indispensable in industries dealing with slurries and abrasive materials.

The open front design of semi-open impellers provides excellent access for cleaning and maintenance, reducing downtime in industrial operations. These pumps maintain reasonable efficiency while offering superior reliability when handling contaminated or particle-laden fluids. The robust construction typically features wear-resistant materials to withstand abrasive conditions common in mining, wastewater treatment, and chemical processing applications.

Manufacturing quality plays a important role in semi-open pump performance, with leading global manufacturers focusing on precision engineering and durable materials. The design allows for easier inspection and maintenance compared to fully enclosed alternatives, making them cost-effective solutions for demanding industrial environments where reliability is paramount.

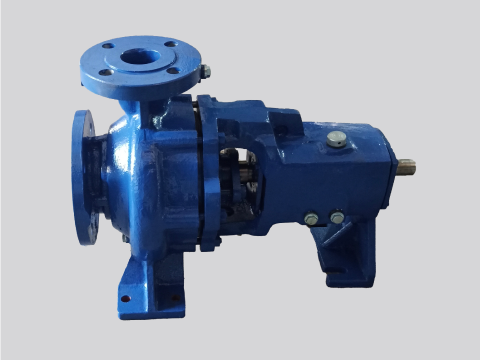

What is a Closed Centrifugal Pump?

A closed centrifugal pump utilizes an impeller completely enclosed by both front and back shrouds, creating a sealed chamber that optimizes fluid flow efficiency. This design minimizes internal recirculation and turbulence, resulting in higher hydraulic efficiency and better performance with clean liquids. Closed impellers are the preferred choice for applications requiring maximum energy efficiency and precise flow control.

The enclosed design provides superior performance characteristics, including higher head generation and improved suction capabilities compared to semi-open alternatives. These pumps excel in applications involving clean water, refined chemicals, and processed liquids where efficiency and performance take priority over maintenance convenience. The sealed impeller chamber reduces energy losses and delivers consistent performance across varying operating conditions.

High-efficiency pumps increasingly feature closed impeller designs to meet stringent energy consumption requirements and environmental regulations. The precision engineering required for closed impellers demands advanced manufacturing capabilities, making quality selection important for optimal performance and longevity in industrial applications.

Semi-Open vs Closed Impellers: Technical Differences

The fundamental difference between semi-open and closed impellers lies in their hydraulic design and flow characteristics. Semi-open impellers feature an open front that allows unrestricted access for particles and debris, while closed impellers create a sealed flow chamber that optimizes efficiency but restricts particle passage. This design difference directly impacts performance, maintenance requirements, and suitable applications for each type.

- Flow Characteristics: Closed impellers generate higher efficiency (typically 5-15% better) due to reduced internal losses and controlled flow patterns. Semi-open designs sacrifice some efficiency for reliability, making them ideal for challenging fluid conditions where closed impellers would fail or require frequent maintenance.

- Construction Complexity: Closed impellers require precise manufacturing tolerances and balanced construction, increasing production costs but delivering superior performance. Semi-open impellers feature simpler construction with fewer wear points, reducing manufacturing complexity and maintenance requirements while providing robust operation in demanding applications.

- Clearance Requirements: Semi-open impellers maintain larger clearances between the impeller and casing, accommodating thermal expansion and operational variations without performance degradation. Closed impellers require tighter tolerances for optimal performance, making them more sensitive to wear and thermal effects.

Advantages of Semi-Open Centrifugal Pumps

1. Superior Solids Handling Capability: Semi-open centrifugal pumps excel at handling fluids containing suspended solids, debris, and abrasive particles without clogging or damage. The open front design allows particles up to 50% of the discharge diameter to pass through, making them ideal for slurry transfer pumps and wastewater applications.

2. Reduced Maintenance Requirements: The accessible design of semi-open impellers simplifies cleaning and maintenance procedures, reducing downtime and operational costs. Inspection and cleaning can be performed without complete pump disassembly, making them practical choices for industrial facilities with limited maintenance resources.

3. Cost-Effective Operation: Lower manufacturing costs and reduced maintenance requirements make semi-open pumps economically attractive for many industrial applications. The robust design tolerates operational variations and contaminated fluids without significant performance degradation, providing reliable service in challenging environments.

4. Versatile Applications: These pumps handle a wide range of fluid viscosities and temperatures, making them suitable for diverse industrial processes. From chemical process pumps to mining applications, semi-open designs provide consistent performance across varying operational conditions.

Advantages of Closed Centrifugal Pumps

1. Maximum Hydraulic Efficiency: Closed centrifugal pumps deliver superior energy efficiency, typically achieving 5-15% higher efficiency compared to semi-open alternatives. This efficiency advantage translates to significant energy savings in continuous operation applications, making them preferred choices for clean liquid pumping systems.

2. Higher Head Generation: The enclosed impeller design generates higher discharge pressures and heads, making closed pumps suitable for high-pressure applications and long-distance fluid transfer. This capability is essential in applications requiring precise pressure control and high-performance standards.

3. Stable Performance Characteristics: Closed impellers provide consistent performance across varying flow conditions, delivering predictable head and flow relationships. This stability is important for process applications requiring precise flow control and system integration with other equipment.

4. Lower NPSH Requirements: The enclosed design typically requires lower Net Positive Suction Head (NPSH), improving suction performance and reducing the risk of cavitation in challenging suction conditions.

Limitations of Each Type

1. Semi-Open Pump Limitations: Lower hydraulic efficiency compared to closed designs results in higher energy consumption for equivalent flow rates. The open design creates internal recirculation losses that reduce overall pump efficiency, particularly at partial flow conditions. Performance can be more sensitive to wear and clearance changes over time.

2. Closed Pump Limitations: Limited solids handling capability makes closed impellers unsuitable for contaminated fluids or applications with suspended particles. Maintenance is more complex and costly, requiring complete disassembly for cleaning or inspection. The precise tolerances required for optimal performance make these pumps more sensitive to operational variations.

3. Application-Specific Considerations: Neither type is universally superior, with the optimal choice depending on specific application requirements. Factors such as fluid characteristics, efficiency requirements, maintenance capabilities, and operational conditions must be carefully evaluated when selecting between semi-open and closed centrifugal pumps.

How to Choose Between Semi-Open and Closed Centrifugal Pumps?

- Fluid Characteristics Assessment: Analyze your fluid properties including particle content, abrasiveness, viscosity, and temperature. Choose semi-open designs for fluids containing solids, debris, or abrasive particles. Select closed impellers for clean liquids where maximum efficiency is required.

- Efficiency vs. Reliability Trade-off: Determine whether energy efficiency or operational reliability takes priority in your application. High-volume, continuous operations with clean fluids benefit from closed impeller efficiency. Applications with challenging fluids or limited maintenance resources favor semi-open reliability.

- Maintenance Infrastructure: Evaluate your facility's maintenance capabilities and downtime tolerance. Semi-open pumps suit facilities with limited maintenance resources or where quick cleaning access is essential. Closed pumps work best where scheduled maintenance is feasible and efficiency gains justify additional complexity.

- Total Cost of Ownership: Consider initial purchase price, energy costs, maintenance expenses, and replacement frequency. Semi-open pumps typically offer lower initial costs and maintenance expenses. Closed pumps may provide better long-term value through energy savings in suitable applications.

Applications of Each Type of Pump

Semi-Open Pump Applications:

- Slurry handling in mining and mineral processing

- Wastewater treatment and sewage pumping

- Pulp and paper industry applications

- Chemical processing with suspended solids

- Food processing with particle-containing fluids

- Industrial cooling systems with contaminated water

Closed Pump Applications:

- Clean water supply and distribution systems

- Chemical processing with clean liquids

- HVAC and building services

- High-pressure washing systems

- Refined petroleum product transfer

- Clean steam condensate systems

Industry-Specific Considerations: Industrial sectors increasingly demand customized industrial pumps that match specific operational requirements and local conditions. Chemical process pumps often require closed designs for efficiency, while mining and wastewater applications typically favor semi-open reliability for handling abrasive materials.

Comparison Table: Semi-Open vs Closed Impeller Pumps

| Parameter | Semi-Open Centrifugal Pump | Closed Centrifugal Pump |

|---|---|---|

| Efficiency | 65-80% | 75-85% |

| Solids Handling | Excellent (up to 50% discharge diameter) | Poor (clean liquids only) |

| Maintenance | Easy access, simple cleaning | Complex disassembly required |

| Initial Cost | Lower | Higher |

| Energy Consumption | Higher due to lower efficiency | Lower due to higher efficiency |

| Clogging Resistance | Excellent | Poor |

| Head Generation | Moderate | High |

| NPSH Requirements | Higher | Lower |

| Wear Resistance | Good | Moderate |

| Performance Stability | Variable with wear | Consistent |

| Typical Applications | Slurry, wastewater, abrasive fluids | Clean water, chemicals, HVAC |

Why Choose Jay Khodiyar Engineering Works?

Jay Khodiyar Pumps stands as a leading centrifugal pump manufacturer, offering both semi-open and closed centrifugal pumps engineered to international standards for industrial conditions. With over 20 years of manufacturing expertise, we specialize in customized industrial pumps designed for diverse applications and challenging operational environments. Our commitment to quality ensures 100% quality assurance with timely delivery and comprehensive after-sales support.

Our state-of-the-art manufacturing facility produces high efficiency pumps that industries trust for critical applications across chemical processing, mining operations, and wastewater treatment facilities. We understand the unique challenges faced by industrial operations including power fluctuations, water quality issues, and extreme operating conditions, designing our pumps accordingly with both standard and customized solutions. Explore our industrial pump solutions at jaykhodiyarpumps.com for expert consultation and competitive pricing tailored to your requirements.

Conclusion & Expert Advice

Selecting between semi-open and closed centrifugal pumps requires careful consideration of application-specific requirements, fluid characteristics, and operational priorities. Semi-open designs excel in challenging conditions with contaminated fluids, while closed impellers deliver superior efficiency for clean liquid applications. The key is matching pump technology to your specific operational needs rather than choosing based on general preferences.

Expert Recommendation: Consult with experienced pump manufacturers who understand your industry's unique challenges and can provide customized solutions. Consider total cost of ownership including energy consumption, maintenance costs, and operational reliability when making your final decision. Get in touch for a custom quote tailored to your specific pumping requirements.

For essential applications, partner with established manufacturers offering comprehensive support, quality assurance, and proven track records in your industry. The right pump selection today determines your operational efficiency and costs for years to come.