Centrifugal Pumps: Most Common Challenges & Solutions in Various Applications

September 30, 2024

Centrifugal Pumps for Pharmaceutical Industry

December 5, 2024In high-heat industries like power generation, oil and gas, and chemical processing, controlling equipment temperatures is essential for efficiency and safety.

Air-cooled pump is a high temperature industrial heat pump that offers a reliable solution by using ambient air to dissipate heat, making them ideal for environments where water resources are scarce or where traditional cooling methods aren't feasible.

These high temperature industrial heat pumps provide continuous cooling, ensuring maintained temperature and smooth operations in demanding conditions.

By preventing overheating, air-cooled pumps help avoid equipment malfunctions and costly downtime.

Air Cooled Pumps: Explained in Detail

Air-cooled pumps are specialized mechanical devices designed to transfer heat from a system using ambient air, rather than water, to maintain optimal operating temperatures. These pumps are crucial in industries where cooling requirements are high, but water is either unavailable or impractical to use.

The primary function of a high temperature industrial heat pump is to dissipate the heat generated by fluid circulation, ensuring that the pump and associated systems remain within their safe operating temperature range.

How Industrial Heat Pump Works?

Unlike traditional water-cooled pumps, which use a water source to absorb and carry away heat, air-cooled pumps rely on air moving over cooling fins or heat exchangers to draw heat away.

This process is particularly useful in remote locations or facilities where water scarcity or contamination concerns make water cooling challenging. Air-cooled pumps are typically equipped with large surface areas and fan systems to maximize airflow, which enhances the heat dissipation process.

Applications Of Air Cooled Pump

Oil and Gas

Used on offshore platforms and remote oilfields where water is scarce, ensuring efficient heat management in harsh conditions.Power Generation

In thermal and renewable power plants to circulate cooling fluids and maintain optimal temperature for equipment.Chemical & Petrochemical

Essential in refineries and chemical plants to cool high-temperature processes and equipment like reactors and heat exchangers.

Manufacturing

In industries like metal processing and heavy machinery cooling, air-cooled pumps prevent overheating of equipment.Food & Beverage

Maintains cooling systems for processing equipment, preventing overheating in temperature-sensitive processes.Mining

Used to cool ventilation systems and mining equipment in extreme environments.

Advantages of Our Air-Cooled Pump

Water Conservation: Reduces dependence on water sources, making them ideal for water-scarce regions or environments with limited access to water.

Energy Efficiency: Consumes less energy compared to traditional water-cooled systems, reducing operational costs and improving overall energy efficiency.

Low Maintenance: Fewer components to maintain than water-cooled systems, leading to lower maintenance costs and reduced downtime.

Durability: Designed to withstand harsh environments and extreme temperatures, offering long service life in challenging conditions.

Compact Design: Requires less infrastructure than water-cooled systems, saving space and installation costs.

Environmental Sustainability: Eliminates water consumption and reduces the risk of water contamination, supporting eco-friendly operations.

Adaptability: Suitable for diverse industries, including oil & gas, power generation, chemical processing, and manufacturing, where high-temperature management is critical.

Environmental Benefits of Our Air-Cooled Pump

- Water Conservation:

Air-cooled pumps eliminate the need for water in the cooling process, conserving valuable water resources, especially in water-scarce regions. - Low Carbon Emissions :

Air-cooled systems typically consume less energy than water-cooled systems, leading to reduced carbon emissions from power generation. - Air Quality Enhancement:

By not requiring water treatment chemicals (used in water-cooled systems), air-cooled pumps help prevent the release of harmful substances into the air and water. - Lower Noise Pollution:

Air-cooled systems can be designed to operate more quietly, reducing noise pollution in industrial areas and improving the local environment. - Renewable Energy :

Air-cooled pumps often pair well with renewable energy systems, such as solar or wind power, due to their lower energy consumption. - Sustainability in Extreme Environments:

Air-cooled pumps are effective in extreme environments (high temperatures, arid areas), offering a sustainable solution without relying on external water sources.

Why Use Air-Cooled Pumps for High-Heat Industrial Operations?

- Efficient Heat Dissipation: Industrial heat pump temperature range is high as it doesn't rely on water, making them more effective in hot environments.

- Lower Maintenance: Fewer components (like cooling towers and water pumps) mean reduced risk of mechanical failure and lower maintenance needs.

- Energy and Water Savings: They consume less energy than water-cooled systems and eliminate the need for large amounts of water, helping conserve valuable resources and save up to 70% of energy costs.

- Environmental Benefits: No thermal discharge or water pollution, making them eco-friendly in sensitive or water-scarce regions.

- Robust in Harsh Conditions: Air-cooled systems are more durable in extreme heat and harsh industrial settings, with less risk of corrosion.

Why Choose Our Air-Cooled Pumps?

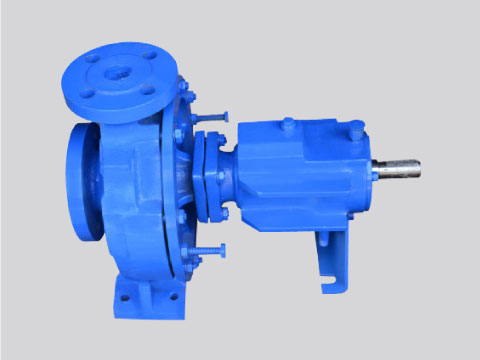

At Jay Khodiyar Engineering, our air-cooled pumps are engineered for optimal performance in high-heat industrial environments. These high temperature industrial heat pumps are ideal for any industry with the toughest environment and smooth operation.

Features of Our Air-Cooled Pumps

- Dynamically Balanced Closed Impeller

- Low Maintenance

- Smart Shaft Design

- Maximum Components Interchangeability

- Highly Efficient

- Strong Construction

Air Cooled Pump Video

Technical Specifications of Our Air-Cooled Pumps

| Capacity | UP TO 40 m3 / hr |

|---|---|

| Head | UP TO 40 m3 / hr |

| Size | 25mm to 80mm |

| Speed | UP TO 3000 R.P.M |

| Pressure | UP TO 12Kg. /cm2 |

| M.O.C. | C.I, C.S, S.S.304, 316, Alloy-20 (Other MOC can be Supply on Request) |

Jay Khodiyar Engineering is the leading industrial heat pump manufacturer in India. With years of experience in this industry, we never fail to deliver durable, reliable, and low-maintenance pumping solutions.

Choose our air-cooled pumps for a combination of advanced technology, sustainability, and exceptional service.