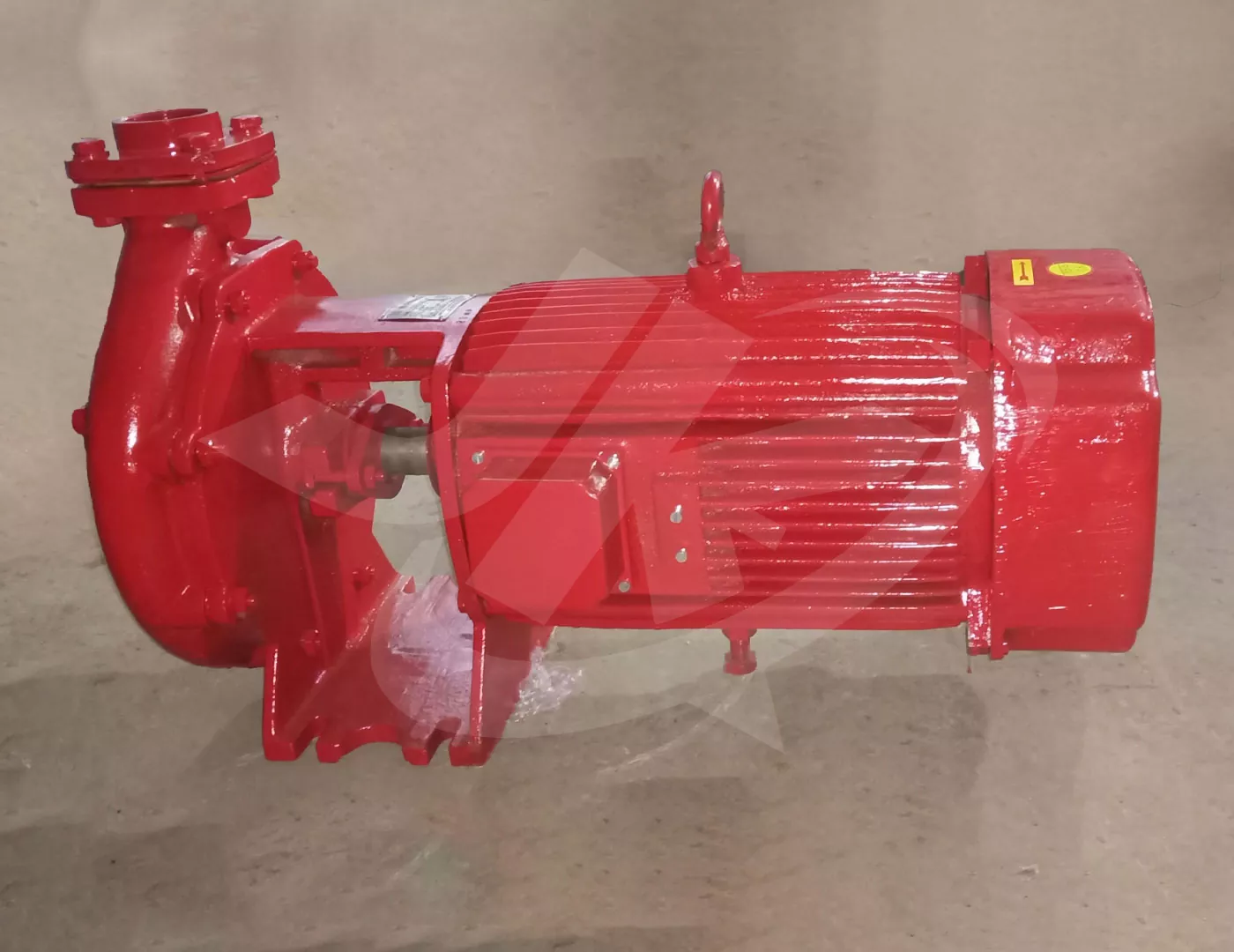

Monoblock Pump Manufacturer In India

Being one of the trusted industrial pump manufacturers and suppliers in India, we serve our customers with the best-in-class range of monoblock pumps that includes centrifugal monoblock pumps, agriculture monoblock water pumps, submersible pumps, and booster pumps.

Our innovative range of monoblock pumps is designed to add value to customer industrial processes by ensuring superior performance in critical conditions.

Jay Khodiyar Engineering Works monoblock pumps are the most cost-effective choice for reliable and efficient pumping. We also offer customized Monoblock Pump according to diverse industrial requirements at the most affordable prices.

- Rugged Design

- Superior Performance

- Durability

- Cost Saving

- Increased Productivity

- Easy Maintenance

| Head | up to 85 mtr/h/ hr |

|---|---|

| Capacity | up to 263 m3/hr/ hr |

| Discharge Size | 25 mm to 100 mm |

| Power Rating | 1.0 HP to 20 HP Three phase 0.5 HP to 2.0 HP Single phase |

| HP | upto 40 HP |

| Speed | up to 2880/1450 RPM |

| M.O.C. | C.I., CS, SS-304, SS 316, Bronze, etc |

| Impeller | CI IS 210 FG 200 Bronze/SS410/304/316/h/ hr |

|---|---|

| Delivery Casing | CI IS 210 FG 200 / hr |

| Motor Body | CI IS 210 FG 200 |

| Shaft | Carbon Steel C40 SS410/304/316 |

| Shaft Sleeve | SS 410 Bronze (LTB2) |

| Protection | IP 44 IP 55 |

| Sealing | Gland Packed Mechanical Seat |

Download Monoblock Pump Catalog

Want to Streamline Your Industrial Processes?

Applications

Chemical Industry

Electroplating Plants

Metallurgical Industries

Steel And Stainless Steel Pickling Lines

Evaporation And Regeneration Units

Wet Flue Gas Cleaning Systems

Exhaust Air Scrubbing

Industrial Wastewater Treatment

Find the Ideal Pump Solutions Tailored to Your Needs Right Here!

What is a Monoblock Pump?

A monoblock pump is a mechanical device in which the motor and pump are assembled in a single unit. With all the parts mounted on a single shaft, this pump has the unique feature of eliminating losses as the single shaft design helps in it. These pumps work by converting rotational kinetic energy to the hydrodynamic energy of water flow for improved reliability and efficiency.

How Does Monoblock Pump Work?

- The motor rotates the impeller inside the pump casing and generates a centrifugal force that pushes the liquid to the outer edges of the impeller blades.

- The impeller vanes give water kinetic energy.

- Water eventually exits and passes through a volute.

How to Install a Monoblock Pump?

Prepare the Foundation

Start with preparing a level concrete foundation for mounting the monoblock using appropriate bolts. Use prescribed pipe sizes.

Place the Pump Center Line

Install the pump in a manner that distance from the pump center to the water surface is 3-6 meters away.

Attach the Foot Valve

Attach the foot valve at the end of the suction pipe and make sure it is completely submerged in water. Reduce pipe fittings to minimize losses.

Insulate Electrical Joints

Ensure all electrical joints are accurately and adequately insulated. Connect the cable to the starter terminals to avoid loose connections.

Maintenance Tips for Monoblock Pumps

- Check Mechanical Seals

- Lubricate as per Guidelines

- Check Bearing Temperature

- Check Heat Tracing

- Inspect Pump Casing and Motor

- Check for Leaks and Oil level