Our Top Quality Industrial Pumps

For every application that requires a unique flow solution, we got them. Presenting you a range of premium products with the highest use cases and best outcomes!

India's Leading Industrial Pumps Manufacturer

By leveraging decades of expertise, Jay Khodiyar Engineering Works supplies comprehensive industrial pump solutions with unmatched quality and durability.

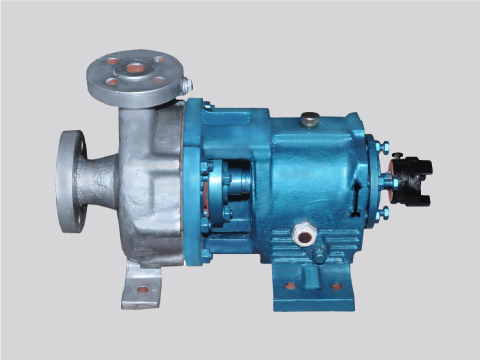

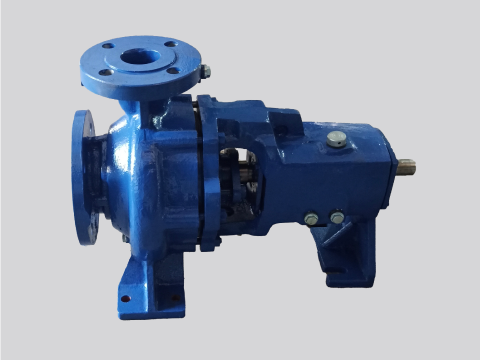

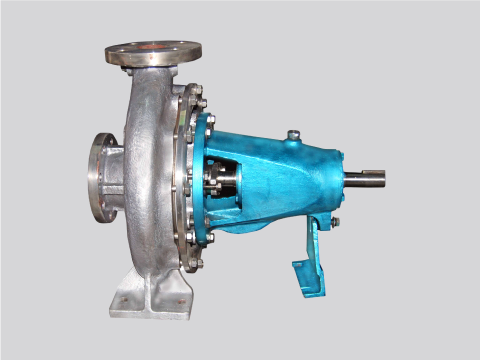

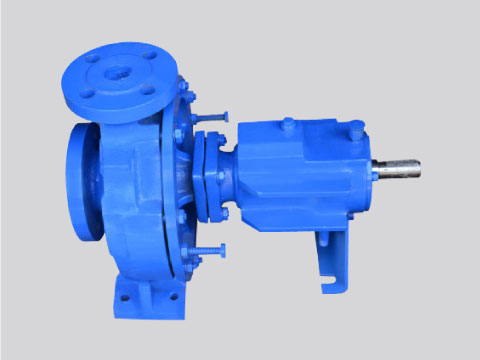

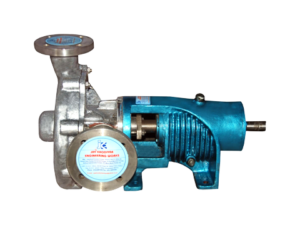

We have 20+ years of experience in manufacturing the best quality industrial pumps available in various shapes and sizes for diverse requirements. Our product range includes Side Suction Centrifugal Pumps, Vertical Submerged Process Pumps, Semi-Open Centrifugal Pump, Closed Impeller Centrifugal Pump, and Chemical Process Pumps, etc.

Our industrial pumps are made of the best quality raw materials and honed using advanced technology and ultra-modern machinery for excellent performance in the toughest environments.

Moreover, we design and manufacture industrial pumps in accordance with the highest quality standards which can be also customized as per the industrial application.

We Are Your Perfect Industrial Pumping Partner!

Industries We Cover

Why Choose Our Industrial Pumps?

For Quick Inquiry!

Get a FREE quote for any pumps from our sales representative.

Download

Our Latest Catalogue

Discover our latest pump models and specifications by downloading our newest Catalogue.

Industrial Pump Videos

Our Blogs

Our Global Reach

Need An Efficient Pump To Streamline Your Industrial Process?

FAQs

Semi Open Impeller Centrifugal Pump | Open Impeller Centrifugal Pump | Closed Impeller Centrifugal Pump | Vertical Submerged Pump | Vertical Submerged Centrifugal Pump | Rotary Gear Pump Manufacturers | Gear Pump Manufacturers | Chemical Process Pump | Chemical Pump | Industrial Pump Manufacturers | Industrial Pump Supplier | Centrifugal Pump Manufacturers | Centrifugal Pump Manufacturers in India | Air Cool Pump Manufacturer | Polypropylene Pump Manufacturer | PP Pump | Monoblock Pump | Monoblock Pump Price | Air Operated Double Diaphragm Pump | AODD Pump | AOD Pump | SS Rotary Gear Pump Manufacturer