Thermic Fluid Hot Oil Pump for Synthetic Oil Transfer

February 3, 2025

Comprehensive Guide to Semi-Open Centrifugal Pump

February 7, 2025Introduction

In the food and beverage industry, checking product quality and smooth production is very important. Centrifugal pumps are key to achieving this. These pumps are commonly used to transfer liquids like milk, juices, and sauces efficiently, while maintaining the required hygiene and reliability standards. With their ability to handle a variety of fluids and operate efficiently, centrifugal pumps are important in helping businesses maintain consistent product quality and optimize production processes.

What is a Centrifugal Pump?

A centrifugal pump is a type of pump that uses rotational energy, typically provided by an electric motor or a turbine, to move liquids. The pump is made of an impeller that spins within a casing, converting energy into dynamic energy, which pushes the liquid through the pump system.

In the food and beverage industry, centrifugal pumps are preferred for their ability to handle high-volume flows and wide ranges of liquids. These pumps are highly effective in transferring fluids such as milk, juices, syrups, and other liquid-based products.

Why Are Centrifugal Pumps Important in Food & Beverage Production?

Centrifugal pumps play a major role in food processing, offering multiple advantages:

- Efficiency: They handle large volumes of liquid, guaranteeing smooth and continuous production processes.

- Sanitation: These pumps are easy to clean and maintain, which is mandatory in the food industry to meet hygiene standards.

- Cost-Effective: They offer a high flow rate at relatively low energy consumption.

- Versatility: Suitable for a wide variety of liquids, including those with low to high visibility.

Types of Food Processing Pumps

The food and beverage industry requires different types of pumps depending on the application. Here are some of the most used pumps:

1. Centrifugal Drum Pump

These pumps are designed for handling liquids in drums or large containers. They are particularly useful in transferring slippery fluids such as oils, syrups, and sauces without the need for wide rehandling.

2. Food Processing Pumps

These pumps are engineered to meet the demands of food production. They are capable of handling both thin and thick liquids, making them ideal for moving everything from water to puree-based products.

3. Positive Displacement Pumps

Similar to centrifugal pumps, positive displacement pumps work by collecting a fixed amount of liquid and forcing it through the system. While they are more commonly used for highly thick liquids, they are sometimes preferred for certain food applications where accuracy is central.

4. Food & Beverage Pumps

These are specialized centrifugal pumps designed specifically for the food and beverage industry. They are made to handle a variety of fluids while maintaining hygiene and efficiency throughout the process.

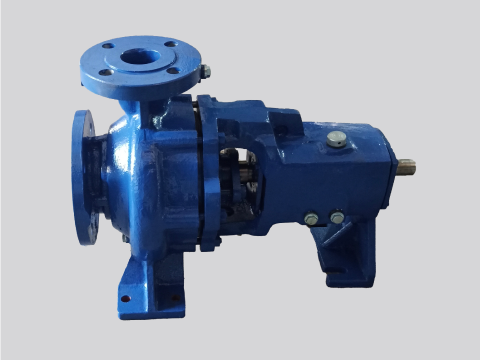

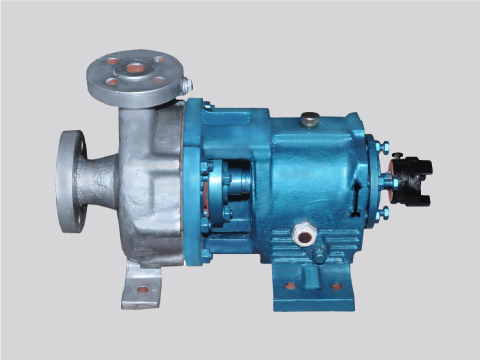

Types Of Centrifugal Pump Jay Khodiyar Provides:

Designed with an inlet on the side of the casing, this pump is space-efficient and guarantees smooth suction with minimal turbulence, making it suitable for applications where installation space is limited.

Features a fully enclosed impeller that enhances efficiency and reduces wear, making it ideal for handling clean or slightly contaminated fluids while maintaining stable pressure and flow.

With a partially enclosed impeller, this pump can handle larger particles and suspended solids, balancing efficiency and durability for various fluid-handling applications.

How to Choose the Right Centrifugal Pump for Food Processing

Selecting the right centrifugal pump for food processing includes various factors:

- Liquid Details: Is the liquid thin or viscous? Centrifugal pumps are best for liquids with lower viscosity.

- Flow Rate Needs: Calculate the required flow rate to confirm the pump can handle the volume of liquid within your production timelines.

- Hygiene and Sanitation: Choose a pump that can be easily cleaned and sanitized to food safety regulations.

- Material Compatibility: See that the materials of the pump are compatible with the types of food products you're processing.

Applications of Centrifugal Pumps in Food & Beverages

Centrifugal pumps are used for various applications in food and beverage production:

- Juice and Beverage Transfer: Efficiently moving juices, smoothies, and other liquid beverages.

- Flow Rate Needs: Calculate the required flow rate to guarantee the pump can handle the volume of liquid within your production timelines.

- Hygiene and Sanitation: Choose a pump that can be easily cleaned and sanitized to meet food safety regulations.

- Material Compatibility: Confirm that the materials of the pump are compatible with the types of food products you're processing.

Conclusion

Centrifugal pumps are necessary in the food and beverage industry, offering versatility, reliability, and efficiency for various applications. Whether it’s transferring dairy, juices, or sauces, Jay Khodiyar Engineering Works provides the best centrifugal pumps designed for critical food processing applications.

For more information about our centrifugal pumps and other industrial pump solutions, contact us today.