Top 10 Reasons Why Industrial Pumps Fail (And How to Prevent Them)

August 13, 2025

A Complete Guide to Rotary Gear Pumps

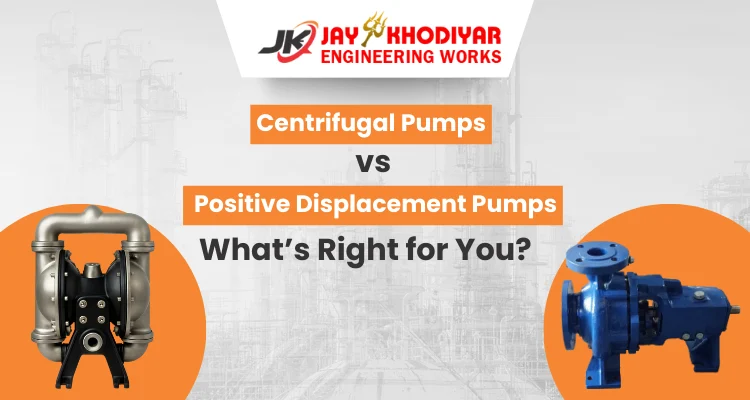

September 30, 2025Choosing the right industrial pump is one of the most critical decisions for any project engineer, procurement head, or operations manager. The wrong choice can lead to operational inefficiency, frequent downtime, and escalating maintenance costs. The right choice, however, ensures reliability, optimizes energy consumption, and protects your bottom line.

At the heart of this decision often lies a fundamental question: should you use a centrifugal pump or a positive displacement (PD) pump?

These two categories represent the vast majority of pumps used in industries like chemical processing, water treatment, pharmaceuticals, and agriculture. Understanding their core differences isn't just technical trivia; it's the key to unlocking maximum performance for your specific application.

As a leading pump manufacturer in India, we at Jay Khodiyar Pumps have guided countless clients through this selection process. This comprehensive guide will demystify the centrifugal vs positive displacement pump debate, giving you the clarity to make an informed, cost-effective decision.

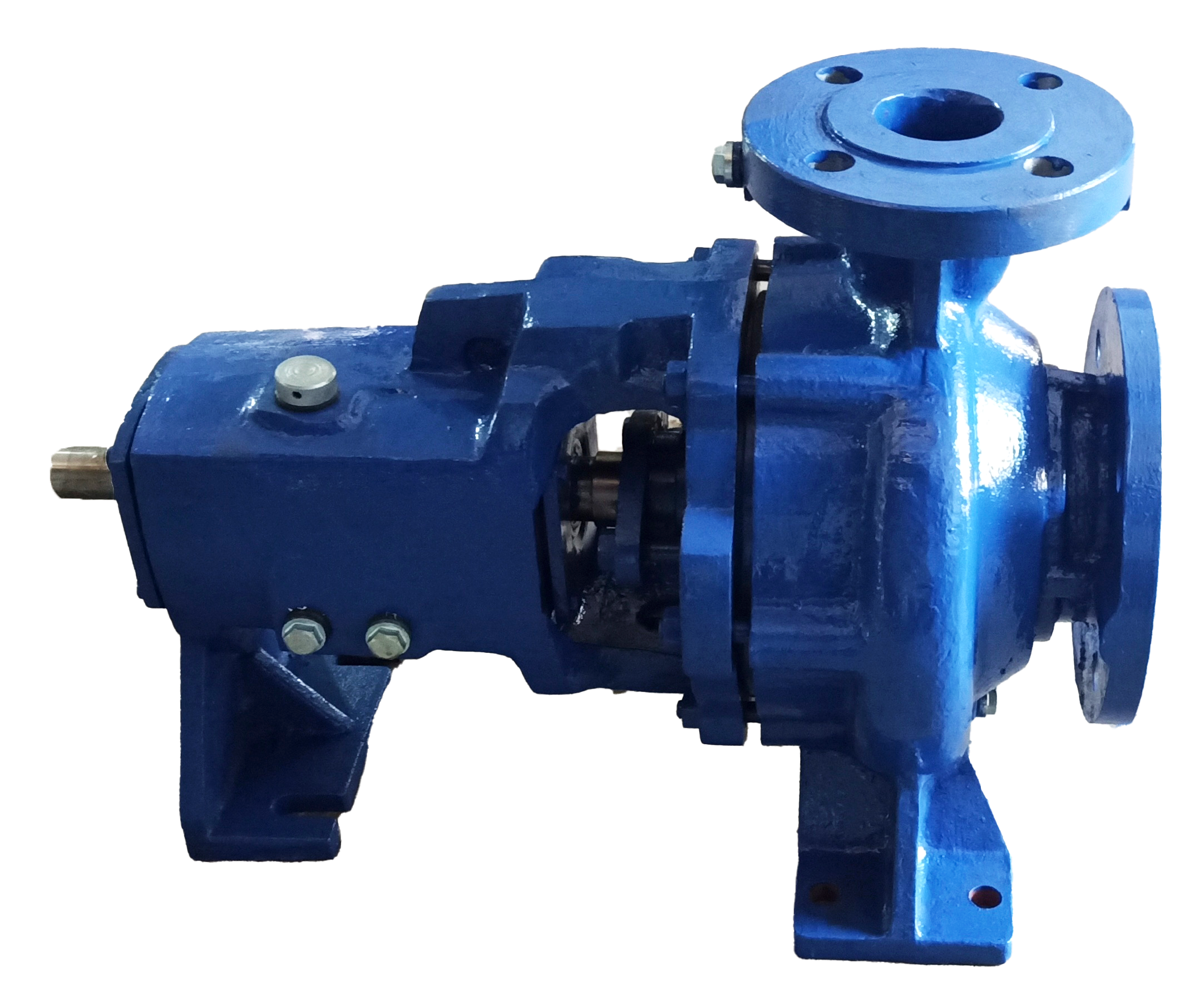

What is a Centrifugal Pump?

A centrifugal pump is a rotodynamic pump that moves fluid by transferring rotational energy from a motor to an impeller. Think of it like a spinning slingshot for liquids. As the impeller spins at high speed, it flings the fluid outwards, converting velocity into pressure that pushes the fluid through the discharge outlet.

The working principle relies on creating a pressure differential. The spinning impeller creates a low-pressure zone at its center (the eye), which draws fluid in. This fluid is then accelerated radially outward by the impeller vanes and discharged at high velocity into a casing (volute), where the high velocity is converted into high pressure.

At Jay Khodiyar Pumps, we offer several types of centrifugal pumps customized for diverse needs, including our robust JKCIP Series (Closed Impeller) and versatile JKSCP Series (Semi-Open Impeller), designed for everything from clear water to light chemical transfer.

Common Applications of Centrifugal Pumps:

- Water supply and circulation in municipal and residential systems.

- Boiler feed and cooling tower applications.

- Irrigation and large-scale agricultural water transfer.

- General transfer of low-viscosity fluids like light fuels, solvents, and chemicals.

What is a Positive Displacement Pump?

A positive displacement (PD) pump works by trapping a fixed amount of fluid and then forcing (displacing) that trapped volume into the discharge pipe. Unlike a centrifugal pump that generates pressure via velocity, a PD pump delivers a constant flow rate regardless of the system's back pressure.

The mechanism is similar to a syringe. As you pull the plunger back, it traps a fixed volume of liquid. Pushing the plunger forward displaces that exact volume. PD pumps use components like gears, lobes, pistons, or diaphragms to create these sealed, moving cavities.

There are two main categories:

- Rotary Pumps: Use rotating elements like gears or lobes to move fluid. Our SS Rotary Gear Pumps are a prime example, excelling at handling viscous oils and chemicals.

- Reciprocating Pumps: Use a back-and-forth motion of pistons or diaphragms. Our Air Operated Double Diaphragm (AODD) Pumps fall into this category, valued for their ability to handle abrasive slurries and shear-sensitive products.

Common Applications of Positive Displacement Pumps:

- Pumping viscous fluids like oils, resins, and molasses.

- High-pressure applications like hydraulic systems.

- Precise dosing and metering in chemical and pharmaceutical industries.

- Handling shear-sensitive fluids like foods, polymers, and biological solutions.

- Pumping abrasive slurries and sludge, often using our durable Mud Pumps.

What Are the Differences Between Centrifugal and Positive Displacement Pumps?

Understanding the fundamental difference between a centrifugal and a positive displacement pump is crucial for proper pump selection. Their distinct operating principles lead to vastly different performance characteristics. Here’s a breakdown of the most important distinctions.

1. Flow Characteristics and Pressure

- Centrifugal Pump: The flow rate is variable and is highly dependent on system pressure (head). As pressure increases, the flow rate decreases. This relationship is shown on a pump's performance curve.

- Positive Displacement Pump: The flow rate is nearly constant, regardless of system pressure. It delivers a fixed volume of fluid with each revolution or stroke. Increasing pressure will not significantly decrease the flow rate until the pump's pressure limit or the motor's power limit is reached.

Takeaway: If your application requires a consistent flow rate despite pressure fluctuations, a positive displacement pump is the clear winner.

2. Viscosity Handling

- Centrifugal Pump: Performance drops sharply as fluid viscosity increases. The high speed of the impeller creates significant friction with thick fluids, leading to reduced flow and efficiency. They are best suited for water-like fluids (typically under 300 cSt).

- Positive Displacement Pump: Performance often improves with higher viscosity. The thicker fluid helps seal the clearances within the pump, increasing volumetric efficiency. PD pumps like our Rotary Gear Pumps can handle fluids with viscosities into the thousands or even hundreds of thousands of cSt.

Takeaway: For thick, viscous liquids like crude oil, syrups, or polymers, a positive displacement pump is essential.

3. Efficiency Comparison

When comparing centrifugal pump vs positive displacement pump efficiency, context is everything.

- A centrifugal pump is highly efficient when operating at its Best Efficiency Point (BEP) for a specific flow rate and pressure with a low-viscosity fluid.

- A positive displacement pump maintains high efficiency across a wide range of pressures and is significantly more efficient when handling viscous fluids where a centrifugal pump would fail.

Takeaway: Efficiency depends entirely on the application. For high-volume water transfer, a centrifugal pump is more efficient. For high-pressure, high-viscosity pumping, a PD pump is the more efficient choice.

4. Priming and Suction Lift

- Centrifugal Pump: Most standard centrifugal pumps are not self-priming. They must be filled with liquid (primed) before start-up because they cannot pump air effectively to create a suction lift. Some specialized designs exist, but standard models require a flooded suction or a priming system.

- Positive Displacement Pump: Most PD pumps are self-priming. They can effectively pump air to create a vacuum in the suction line, allowing them to lift fluid from a lower level. This makes them ideal for applications where the pump is located above the fluid source.

Takeaway: If your system requires suction lift or could run dry intermittently, a self-priming positive displacement pump is a more reliable option.

Advantages and Disadvantages: A Quick Comparison

To simplify your decision, here’s a clear breakdown of the pros and cons for each pump type.

What are the Advantages of Centrifugal Pumps?

✅ High Flow Rates: Unmatched for moving large volumes of low-viscosity liquid quickly.

✅ Simple Design: Fewer moving parts mean they are generally easier and less expensive to maintain.

✅ Lower Initial Cost: Typically have a lower purchase price compared to PD pumps for similar flow applications.

✅ Compact & Smooth Operation: Their rotary design allows for smooth, pulsation-free flow and a smaller footprint.

What are the Disadvantages of Centrifugal Pumps?

❌ Poor Viscosity Handling: Efficiency plummets with thicker fluids.

❌ Requires Priming: Not self-priming, which can complicate system design.

❌ Variable Flow: Flow rate is sensitive to changes in system pressure.

❌ Shear Damage: The high-speed impeller can damage or alter shear-sensitive fluids like emulsions or biological cells.

What are the Advantages of Positive Displacement Pumps?

✅ Excellent Viscosity Handling: Ideal for pumping thick, viscous, and abrasive fluids.

✅ Constant Flow Rate: Delivers a steady, predictable flow regardless of pressure, perfect for metering and dosing.

✅ Self-Priming: Can create a strong suction lift and handle air pockets.

✅ Gentle Action: The slower, deliberate pumping action is gentle on shear-sensitive fluids.

What are the Disadvantages of Positive Displacement Pumps?

❌ Lower Flow Rates: Generally, cannot match the high-volume capacity of centrifugal pumps.

❌ More Complex Design: Tighter tolerances and more moving parts can lead to higher maintenance requirements.

❌ Higher Initial Cost: Can be more expensive upfront, especially for specialized designs.

❌ Requires Pressure Relief: Must have a pressure relief valve to protect the pump and system from over-pressurization if the discharge is blocked.

How to Choose the Right Pump for Your Industry?

Making the right choice comes down to analyzing your specific application needs. Use this pump selection guide for industries to steer your decision.

Key Factors to Consider:

1. Fluid Properties:

A. Viscosity:

Is the fluid thin like water or thick like honey? This is often the first and most important deciding factor.

B. Abrasiveness:

Does the fluid contain hard solids that could wear down components? Our Polypropylene Pumps or heavy-duty Mud Pumps are designed for such challenges.

C. Shear Sensitivity:

Will high speeds damage the fluid's structure (e.g., food products, polymers)?

D. Chemical Compatibility:

The pump's materials must resist corrosion from the fluid. We offer solutions in SS, PP, and other resistant materials.

2. Operational Requirements:

A. Flow Rate:

How much fluid do you need to move per minute or hour (GPM, m³/hr)?

B. Pressure/Head:

How much pressure is needed to overcome system friction and elevation changes?

C. Suction Conditions:

Is there a suction lift, or is the pump's inlet flooded?

Industry-Specific Recommendations:

- Chemical Processing: This is highly dependent on the specific chemical. For transferring low-viscosity solvents, a Chemical Process Centrifugal Pump is ideal. For dosing viscous additives or handling corrosive slurries, an AODD Pump or SS Rotary Gear Pump is superior.

- Water & Wastewater Treatment: Centrifugal pumps dominate for moving large volumes of water. However, for pumping thick sludge, slurries, and chemical dosing (e.g., polymers), positive displacement pumps are required.

- Oil & Gas: PD pumps are the standard for handling viscous crude oil, lubricants, and bitumen. Centrifugal pumps are used for transferring refined, lighter hydrocarbons and for water injection systems.

- Food & Beverage: Positive displacement pumps are often preferred for their gentle handling of shear-sensitive products like yogurt, pie fillings, and sauces. Centrifugal pumps are used for utility applications like clean-in-place (CIP) systems and water transfer.

- Agriculture: High-flow centrifugal pumps are perfect for irrigation. Smaller PD pumps might be used for precise fertilizer or pesticide application.

The Final Verdict: Which Pump Is Right for You?

The debate of centrifugal vs positive displacement pumps doesn't have a single winner. The best pump is always the one that is correctly matched to its application.

Choose a Centrifugal Pump if:

- You are moving large volumes of low-viscosity fluid (like water).

- Your system has low back pressure.

- A variable flow rate is acceptable.

- Initial cost and simple maintenance are top priorities.

Choose a Positive Displacement Pump if:

- You are handling high-viscosity or shear-sensitive fluids.

- You need a constant, precise flow rate for dosing or metering.

- Your system has high back pressure.

- You require self-priming capability or suction lift.

Making the right selection at the outset saves enormous amounts of time, money, and frustration down the line. It ensures your operations run smoothly, efficiently, and reliably.

Your Partner in Pumping Solutions

At Jay Khodiyar Pumps, we don’t just sell pumps; we provide engineered solutions. From our robust centrifugal process pumps to our specialized rotary gear and AODD pumps, we have the technology and expertise to meet your toughest challenges.

Ready to find the perfect pump for your needs?

- Explore Our Full Range of Industrial Pumps

- Speak with Our Engineering Team Today