Industrial Pumps Maintenance Checklist: 10 Easy Ways

December 15, 2023

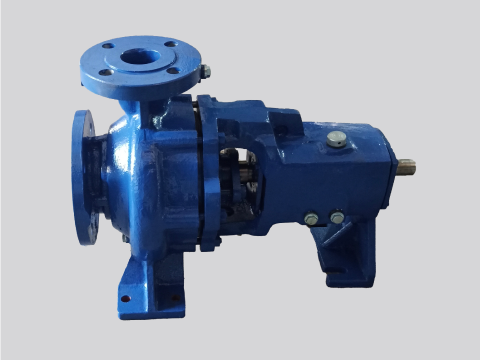

Top Centrifugal Pumps Manufacturer in India

January 30, 2024Centrifugal pumps are commonly used in many industries to move liquids from one place to another.

If you use centrifugal pumps, it's important to understand how efficient they are operating. This will help with proper system design and troubleshooting.

In this post, we'll walk you through the steps to calculate the efficiency of a centrifugal pump all by yourself.

Understand the Basics of Centrifugal Pump Efficiency

First, let's review what pump efficiency means. Pump efficiency is a measure of how much power is converted by the pump into flow energy.

It is calculated as the ratio of power output to power input and is typically expressed as a percentage.

Higher efficiency values indicate less energy is being lost during the pumping process.

So if you had a pump that took in 10 HP of power, and converted 8 HP into hydraulic energy, its efficiency would be 8/10 or 80%.

Pretty simple, right?

The key is you need to know the input power and the useful output power.

Key Parameters Needed for Efficiency Calculation

To determine centrifugal pump efficiency, you need to measure three key parameters:

- Flow Rate (Q) — This is the volume flow per time unit. It is commonly measured in gallons per minute (GPM).

- Head Pressure (H) —This is the height that which the pump can raise the liquid. It is expressed in feet of fluid.

- Input Power (P) — This is the shaft power supplied to drive the pump. It is usually measured in horsepower (HP).

You can obtain these values from the pump performance curves, system instrumentation like pressure gauges, or through pump testing.

Calculate the Hydraulic Power

Now that you have the flow rate, head, and input power, you can calculate the hydraulic power. Hydraulic power is the useful power imparted to the pumped fluid. Here is the formula to calculate it:

Hydraulic Power = (Q x H x sp. gr. x 8.33 lbs/gal) / 33,000 ft-lbs/min/HP

Where:

- Q = flow rate in GPM

- H = pump head in feet

- sp. gr. = specific gravity of liquid

- 8.33 lbs/gal is the density of water

- 33,000 converts the units to horsepower

Plug in the values you obtained for Q, H, and specific gravity into this formula to get the hydraulic power in HP.

Calculate the Overall Centrifugal Pump Efficiency

You're on the last step now. To obtain the pump efficiency, simply divide the hydraulic power by the input power and multiply by 100 to get a percentage.

Centrifugal Pump Efficiency Formula:

Centrifugal Pump Efficiency = (Hydraulic Power) / (Input Power) x 100%

Input the hydraulic power from the previous step and the measured input power into this formula.

It will give you the efficiency percentage of your centrifugal pump.

If you get an efficiency of 50%, that tells you that 50% of the input power is converted into useful work by the pump. The rest is lost to friction and other losses.

A good pump efficiency is usually 60-80%.

Conclusion

Calculating the efficiency of a centrifugal pump is quite straightforward once you understand what parameters to measure.

Knowing your pump's efficiency will help optimize your pumping system and avoid wasting excess energy.

That said, we hope this overview provides you with a good understanding of how to calculate centrifugal pump efficiency yourself.

If you still have any questions or looking for a highly versatile & low-maintenance industrial pump manufacturer in India, Jay Khodiyar Pumps has got just the right centrifugal pump for all your needs.