Chemical Pumps: All You Need to Know

July 17, 2024

Industrial Pump Types: Main Benefits, Applications, and Considerations

August 13, 2024Wastewater treatment plants are complex systems that rely on a variety of equipment to effectively cleanse and purify used water. One of the most crucial components are pumps used in wastewater treatment plants.

Industrial pumps are responsible for constantly moving wastewater through various stages of treatment, ensuring smooth and efficient operation.

The specific type of industrial pump employed depends on the characteristics of the wastewater and the intended purpose within the treatment process. Choosing the right pump requires careful considerations like the presence of solids, corrosiveness, and the required flow rates.

From robust centrifugal pumps to versatile diaphragm pumps, a range of industrial pumps play a vital role in keeping our water clean.

Types of Industrial Pumps Used in

Wastewater Treatment Plants

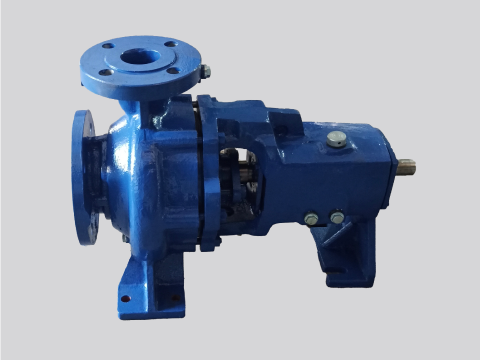

Centrifugal Pumps

Centrifugal pump is a type of dynamic pump that works on the principle of centrifugal force to move fluids through the pump. It is one of the most pumps used in wastewater treatment plant

Centrifugal pumps convert rotational energy from a motor or engine into kinetic energy in the fluid being pumped. This kinetic energy then creates pressure within the pump, pushing the fluid through the pump and into the piping system.

There are different types of centrifugal pumps including single-stage pumps (one impeller) and multi-stage pumps (multiple impellers).

Advantages

- Generally reliable and simple to operate.

- Can handle large flow rates.

- Can operate over a wide range of pressures and flows.

Our Centrifugal Pump’s Features

- Highly Versatile

- Energy Efficient

- High Operating Reliability

- Safe Fluid Handling

- High Productivity

- Low Maintenance

- Heavy Duty Design

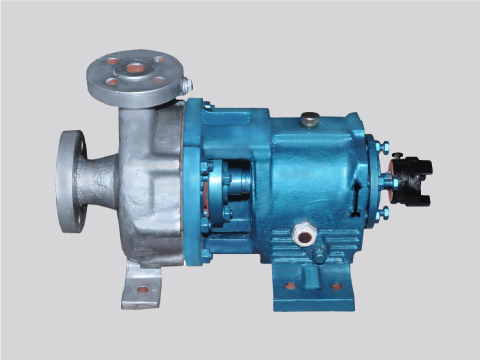

Semi-Open Centrifugal Pumps

Semi-open centrifugal pumps are a specific type of centrifugal pump design that differs from the more common closed impeller design.

Unlike closed impellers that are fully enclosed, semi-open centrifugal pumps have an impeller with vanes that are open on one side. This design allows for easier passage of solids or fibrous materials in the fluid being pumped.

The open side of the impeller allows larger particles or debris to pass through without clogging, making semi-open pumps suitable for handling fluids with moderate solids content or those prone to clogging in a closed impeller design.

Advantages

- Reduces the likelihood of clogging compared to closed impeller centrifugal pumps.

- Handles fluids with suspended solids and fibrous materials better than closed impeller centrifugal pumps.

- Easier to inspect and clean.

Our Semi-Open Centrifugal Pump’s Features:

- Maximum Interchangeability

- Greater Quality Control and Accuracy

- Back Pull–Out Design

- Exclusive Balanced Thrust

- Fully Open Impeller with Back Pumps

- Low Maintenance

Vertical Submerged Process Pumps

Vertical submerged process pumps are a specialized type of centrifugal pump designed for applications where the pump needs to be submerged in the fluid it is pumping.

These pumps are designed to operate with their shaft and impeller assembly arranged vertically. This vertical configuration allows them to be submerged directly into the fluid being pumped.

Vertical submerged process pumps are typically installed inside a tank or sump, with the pump's motor mounted above the liquid level and the pump shaft extending downwards into the liquid.

Advantages

- Ideal for installations where space is limited, as they can be submerged directly into the tank or sump.

- Reduces the NPSH requirement, reducing the risk of cavitation.

- Achieve high hydraulic efficiency, especially in multi-stage configurations.

Our Vertical Submerged Process Pump’s Features:

- High Head Per Stage

- High Capacity

- Low Maintenance

- Robust Design

- Highly Reliable

- Long Life

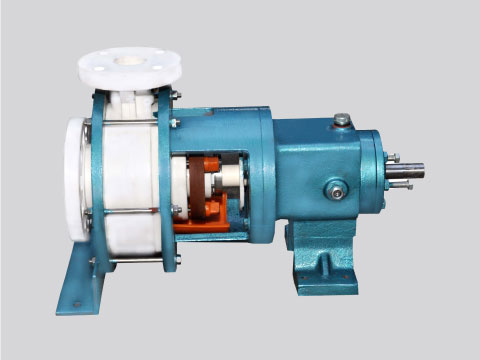

Polypropylene Pumps

Polypropylene pumps are a type of centrifugal pump specifically designed with components made from polypropylene (PP), a thermoplastic polymer known for its excellent chemical resistance and durability.

Polypropylene pumps are constructed using polypropylene for the pump casing, impeller, and other wet parts. Polypropylene is chosen for its resistance to a wide range of corrosive chemicals, including acids, alkalis, and organic solvents.

They are highly resistant to corrosion, making them suitable for pumping aggressive and corrosive fluids in industries such as chemical processing, pharmaceuticals, water treatment, and electroplating.

Advantages

- Resistant to a wide range of chemicals and offers excellent protection against corrosion.

- Lighter compared to metalic pumps, making them easier to handle and install.

- More economical than pumps made from exotic alloys while offering comparable corrosion resistance.

Our Polypropylene Pump’s Features:

- Easy Maintenance

- Strong Construction

- Leak Proof

- Efficient Design

- Corrosion Resistant

Air Operated Double Diaphragm Pumps

Air Operated Double Diaphragm (AODD) pumps are versatile and reliable fluid transfer pumps that operate using compressed air.

These pumps are powered by compressed air, which alternately moves the diaphragms in and out. The reciprocating action creates suction and discharge strokes, allowing for the pumping of liquids, slurries, and viscous fluids.

The air valve system controls the movement of the diaphragms, enabling variable flow rates and pressures based on the air supply.

Advantages

- These industrial pumps can run dry without causing damage to its components.

- Suitable for mobile or portable applications where electricity may not be readily available.

- Easy to maintain.

Our Air Operated Double Diaphragm Pump’s Features:

- Easy Installation & Operation

- No Lubrication Required

- Low Maintenance

- Corrosion Resistance

- Leakproof Design

- Extremely Portable

Why Choose Our Industrial Pumps?

Wastewater treatment plants can’t have smooth and efficient operation without industrial pumps. At Jay Khodiyar Engineering Works, we manufacture high-quality industrial pumps used in wastewater treatment plants.

We offer industrial pumps constructed with standard raw materials and following international quality standards to deliver high efficiency. Keep your wastewater treatment plants running smoothly with our reliable industrial pumps.