Air Cooled Pump for Edible Oil Applications

February 17, 2025

Thermic Fluid Hot Oil Pump for Mineral Oil Industry

March 10, 2025Introduction

In Industrial heating systems, efficient heat transfer is important to maintaining productivity and reducing energy costs. Centrifugal pumps play a crucial role in thermic fluid boilers by providing continuous circulation of high-temperature fluids. These pumps are widely used in various industries, including chemical processing, food production, textiles, and pharmaceuticals, to provide consistent heating and prevent overheating issues.

By choosing the right centrifugal pump for a thermic fluid boiler, businesses can enhance operational efficiency, minimize downtime, and extend the duration of their heating systems. This guide will help you understand the importance of centrifugal pumps, their applications, selection criteria, and maintenance tips to optimize performance.

What is a Centrifugal Pump for a Thermic Fluid Boiler?

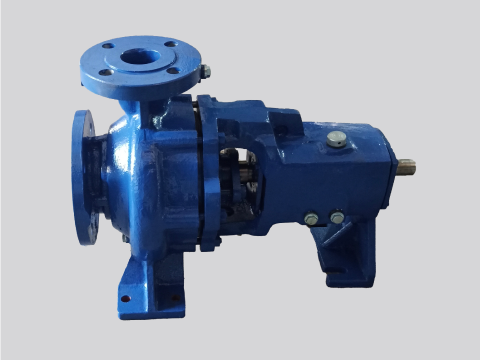

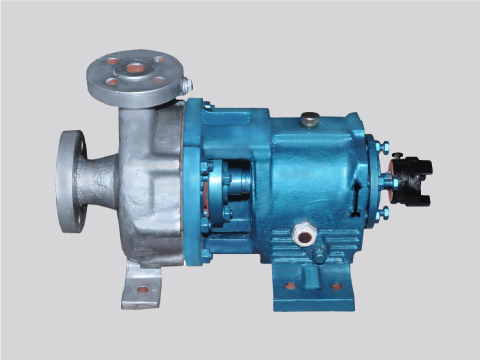

A centrifugal pump for a thermic fluid boiler is a specialized pump designed to circulate thermal fluids efficiently. These pumps handle high-temperature fluids, ensuring smooth heat transfer in industrial applications.

Industries like chemical processing, textiles, and food production depend on these pumps to maintain optimal heating conditions without pressure fluctuations. The primary function of this pump is to move thermic fluid in a closed-loop heating system to facilitate heat exchange processes effectively.

Why Use a Centrifugal Pump for Thermic Fluid Boilers?

When it comes to thermic fluid boilers, choosing the right pump is crucial for efficient heat transfer and system performance. A centrifugal pump is an ideal choice due to its ability to handle high temperatures, low maintenance requirements, and energy efficiency.

Here’s why:

1. Efficient Heat Transfer

Centrifugal pumps are designed to maintain a continuous flow of thermic fluid, guaranteeing perfect heat distribution throughout the system. This prevents temperature fluctuations, improving the efficiency and reliability of the boiler system.

2. Handles High Temperatures

Thermic fluid boilers operate at high temperatures, and centrifugal pumps are built to withstand extreme heat without compromising performance. Their flexible design and heat-resistant materials ensure smooth operation even in demanding industrial applications.

3. Low Maintenance

One of the biggest advantages of centrifugal pumps is their minimal maintenance requirements. With fewer moving parts and no complex sealing mechanisms, these pumps experience less wear and tear, reducing downtime and maintenance costs.

4. Energy Efficient

Centrifugal pumps are highly efficient in circulating thermic fluids, consuming less energy compared to other pump types. Their ability to optimize fluid flow with minimal power consumption helps industries reduce energy costs and improve overall operational efficiency.

5. Long-Lasting Durability

Built with high-quality materials, centrifugal pumps offer long-term durability, even in harsh operating conditions. Their waterproof construction and corrosion-resistant properties make them a reliable choice for thermic fluid boilers, ensuring uninterrupted performance for years.

By choosing a centrifugal pump for your thermic fluid boiler system, you can achieve optimal heat transfer, built efficiency, and long-term cost savings while ensuring smooth industrial operations.

How Does a Centrifugal Pump Work in a Thermic Fluid Boiler?

A centrifugal pump operates using rotational energy supplied by an electric motor. The pump impeller generates velocity, converting it into pressure to move the thermal fluid.

The working principle follows these steps:

-

1.Fluid Enters the Pump: Moved through the suction pipe.

-

2. Impeller Rotation: Creates centrifugal force, increasing fluid flow time.

- 3. Pressure Conversion: Moving energy converts into pressure energy.

- 4. Fluid Discharge: Pumped through the system to maintain boiler efficiency.

- 5. Continuous Circulation: Guarantees a steady flow of thermic fluid without overheating or pressure drops.

Applications of Centrifugal Pumps for Thermic Fluid Boilers

Centrifugal pumps for thermic fluid boilers are specialized equipment important across numerous industrial sectors, offering significant advantages in thermal transfer applications. Their applications extend well beyond basic functionality:

1. Chemical Processing:

2. Textile Industry:

3. Food Processing:

4. Plastic & Rubber Industry:

5. Pharmaceuticals:

Features of a Centrifugal Pump for Thermic Fluid Boilers

Centrifugal pumps play a primary role in thermic fluid boiler systems by ensuring efficient circulation and heat transfer. Their specialized design and flexible features make them the preferred choice for handling high-temperature fluids in industrial applications. Here are the key features that make centrifugal pumps ideal for thermic fluid boilers:

1. Material Durability

Centrifugal pumps for thermic fluid applications are constructed using high-grade materials like cast iron, stainless steel, or special heat-resistant alloys. These materials improve the pump’s durability, ensuring it withstands extreme temperatures and continuous operation without degradation.

2. Seal Protection

To stop fluid leakage and system failures, centrifugal pumps come with advanced sealing mechanisms such as mechanical seals or high-temperature gaskets. These seals ensure reliable performance by preventing leaks, reducing maintenance needs, and enhancing pump efficiency.

3. High-Temperature Resistance

Thermic fluid systems operate at promoted temperatures, requiring pumps that can handle extreme heat without losing efficiency. Centrifugal pumps are specifically engineered with heat-resistant components, allowing them to function smoothly under high-temperature conditions without thermal expansion issues.

4. Corrosion Resistance

Industrial environments often expose pumps to corrosive substances. Corrosion-resistant coatings and stainless-steel components in centrifugal pumps protect against rust, oxidation, and chemical damage, ensuring long-term reliability even in aggressive working conditions.

5. Easy Installation

Centrifugal pumps are designed for quick installation, with compact structures and standard connection fittings that simplify setup. Their user-friendly design allows for quick integration into thermic fluid systems, minimizing downtime and reducing operational complexities.

By incorporating these features, centrifugal pumps ensure efficient, safe, and long-lasting performance in thermic fluid boiler applications, making them a dependable solution for industrial heat transfer needs.

Choosing the Best Centrifugal Pump for a Thermic Fluid Boiler

Consider these factors when selecting a pump:

- Flow Rate: See it matches the boiler requirements.

- Temperature Range: Verify it can withstand operational heat levels.

- Build Quality: Choose durable materials for longevity.

- Energy Efficiency: Look for pumps that optimize power usage.

- Operational Safety: Verify it has robust safety mechanisms to prevent overheating.

| Feature | Description |

|---|---|

| Pump Type | Single-stage, multi-stage centrifugal pumps |

| Temperature Handling | Up to 350°C |

| Material | Cast iron, stainless steel |

| Efficiency | Energy-saving design |

| Application | Chemical, textile, food processing |

| Safety Features | Leak-proof sealing, corrosion resistance |

Common Challenges & Solutions in Using Centrifugal Pumps for Thermic Fluid Boilers

While centrifugal pumps are highly efficient for thermic fluid applications, several technical challenges require specific solutions:

1. High-Temperature Fluid Handling

- Select specialized alloys with high temperature resistance

- Implement proper thermal expansion allowances

- Utilize heat-resistant gaskets and bearings

- Install cooling systems for bearing assemblies

2. Seal Leakages

- Install specialized high-temperature mechanical seals

- Implement appropriate seal flush systems

- Consider magnetic drive pumps for zero-leakage requirements

- Maintain proper seal chamber cooling

3. Pressure Drops

- Design piping systems with minimized restrictions

- Implement proper pump sizing based on system resistance

- Install pressure monitoring systems

- Perform regular cleanings to remove flow-restricting deposits

4. Pump Conditioning

- Install properly designed expansion tanks

- Implement proper venting procedures

- Maintain correct fluid levels through monitoring

- Ensure adequate NPSH at all operating conditions

5. Thermal Shocking

- Implement gradual startup and shutdown procedures

- Install temperature ramping controls

- Design for thermal expansion with flex connections

How to Maintain a Centrifugal Pump for a Thermic Fluid Boiler?

To ensure longevity and efficiency, follow these maintenance tips:

- Regular Inspection: Check for leaks, wear, and tear.

- Maintenance: Keep bearings and mechanical seals properly cleaned.

- Monitor Temperature & Pressure: Avoid overheating and excessive pressure buildup.

- Timely Replacement of Worn Parts: Replace damaged seals and impellers to maintain performance.

Jay Khodiyar Pumps: Leading Manufacturer of Centrifugal Pumps

Founded in 1995, Jay Khodiyar Engineering Works has established itself as a leading industrial pump manufacturer in India. With 20+ years of experience, the company offers high-quality centrifugal pumps for thermic fluid boilers.

Our pumps are:

- ISO Certified, ensuring compliance with global standards.

- Energy-Efficient, reducing operational costs.

- Designed for Heavy-Duty Applications, to withstand industrial demands.

- Customized to Fit Industry Needs, offering specific solutions for different sectors.

Conclusion

Centrifugal pumps are important for efficient heat transfer in thermic fluid boilers, guaranteeing smooth circulation of high-temperature fluids. Whether it’s for chemical pumps, mud pumps, PP pumps, or rotary gear pumps, Jay Khodiyar Engineering Works provides high-quality solutions customized to industrial needs.

For more information about our centrifugal pumps and other industrial pump solutions, contact us today.