Types of Pumps used in the Chemical Industry

August 31, 2024

Centrifugal Pumps: Most Common Challenges & Solutions in Various Applications

September 30, 2024In the dynamic world of industrial manufacturing, pumps play a vital role across a wide range of industries, from oil and gas to water treatment and chemical processing.

The demand for reliable, efficient, and innovative pump solutions has driven the emergence of numerous top-tier industrial pump manufacturers in the USA.

Among the foremost manufacturers, there are few that top the list. In this blog, we’d help you reach the right industrial pump manufacturer in the USA that meets all your requirements.

Let’s hop in!

Industrial Pumps Overview: Types and Industrial Applications

Industrial pumps are critical components in various sectors, serving to move fluids and slurries with precision and efficiency. These pumps come in several types, each designed to handle specific tasks and challenges in different industrial applications.

Types of Industrial Pumps

1. Centrifugal Pumps

These pumps use rotational energy from a rotating impeller to move fluids. They are commonly employed in applications requiring a continuous flow of liquid, such as in water supply, wastewater treatment, and chemical processing. Centrifugal pumps are known for their simplicity, efficiency, and ability to handle large volumes of fluid with relatively low energy consumption.

2. Positive Displacement Pumps

This category includes gear, diaphragm, and peristaltic pumps. Positive displacement pumps move fluid by trapping a fixed amount and forcing it into the discharge pipe. They are ideal for high-viscosity fluids, metering applications, and scenarios where precise dosing is required. Gear pumps are often used in hydraulic systems, diaphragm pumps in chemical handling, and peristaltic pumps in medical and laboratory settings.

3. Diaphragm Pumps

Utilizing a flexible diaphragm to move fluid, these pumps are known for their ability to handle corrosive and abrasive liquids. They are often used in industries such as pharmaceuticals, food and beverage, and chemical processing, where the pump’s design can help prevent contamination and ensure safe fluid handling.

Applications of Industrial Pumps

Water and Wastewater Treatment

Oil and Gas

Chemical Processing

Food and Beverage

Pharmaceuticals

Mining

Marine

Power Generation

Construction

Agriculture

How to Choose the Right Industrial Pump?

Fluid Characteristics

Flow Rate and Pressure

Efficiency and Energy Use

Application and Environment

Maintenance and Cost

Installation and Space

Jay Khodiyar Engineering: Renowned Industrial Pump Manufacturer in the USA

Jay Khodiyar Engineering stands out as a prominent industrial pump manufacturer in the USA, renowned for its high-quality and innovative pumping solutions. Specializing in a diverse range of applications, Jay Khodiyar Engineering offers highly reliable and effective industrial pumps including centrifugal pumps, mud pumps, gear pumps, polypropylene pumps, and more.

Our Top Industrial Pumps

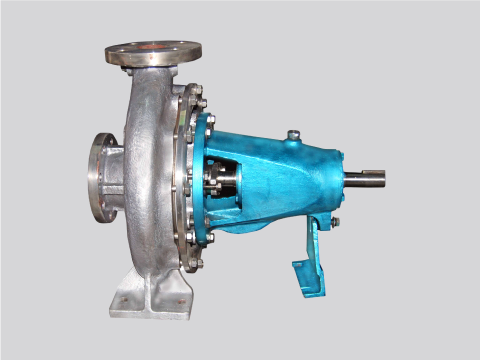

1. Centrifugal Pumps

Ideal for moving large volumes of fluids efficiently, these pumps are widely used in water treatment and industrial processes. They operate by converting rotational energy into fluid flow through an impeller, offering reliable performance for continuous and high-flow applications.

At Jay Khodiyar Pumps, we offer different types of centrifugal pumps including closed impeller centrifugal pump,

side suction centrifugal pump, and semi-open centrifugal pump.

Features

- Highly Versatile

- Energy Efficient

- High Operating Reliability

- Safe Fluid Handling

- High Productivity

- Low Maintenance

- Heavy Duty Design

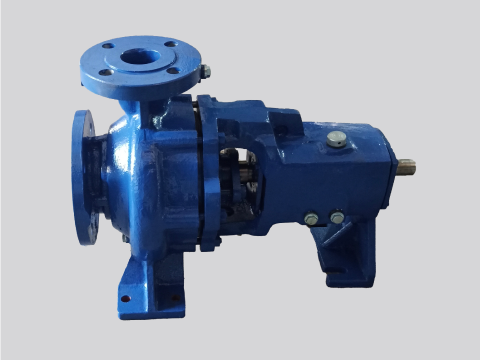

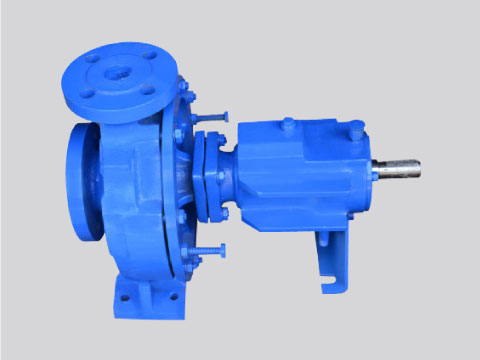

2. Chemical Process Pumps

Designed to handle corrosive and abrasive chemicals, these pumps ensure safe and precise fluid transfer in chemical processing and manufacturing. They feature materials and designs tailored to withstand harsh conditions and maintain the integrity of the fluid.

Features

- High-Efficiency Rate

- Low Power Consumption

- Durable

- Easy To Install

- Low Maintenance

3. Rotary Gear Pumps

Known for their ability to handle high-viscosity fluids and deliver consistent flow, rotary gear pumps are essential in industries such as oil and gas, as well as in hydraulic systems. They provide accurate metering and reliable performance for thick or shear-sensitive liquids.

Features

- Compact Size

- Low Noise

- High Efficiency

- Easy To Maintain

- Low-Cost

- Rugged Design

- Highly Durable

- Long Service Life

4. Mud Pumps

Engineered for demanding environments like drilling operations, mud pumps are robust and durable, capable of handling thick, abrasive slurries. They play a crucial role in maintaining the circulation of drilling fluids and managing the pressures in well-drilling applications.

Features

- Rugged Construction

- Compact Design

- Low Maintenance

- Easy Service

- Soft Gland & Mechanical Seal

- Corrosion Resistant

5. Air-Cooled Pumps

These pumps are designed to operate in environments where water cooling is impractical. Utilizing air to dissipate heat, they are suitable for various industrial applications where space or water availability is limited. Air-cooled pumps offer a practical solution for maintaining performance without the need for extensive cooling infrastructure.

Features

- Dynamically Balanced Closed Impeller

- Low Maintenance

- Maximum Components Interchangeability

- Smart Shaft Design

- Highly Efficient

- Strong Construction

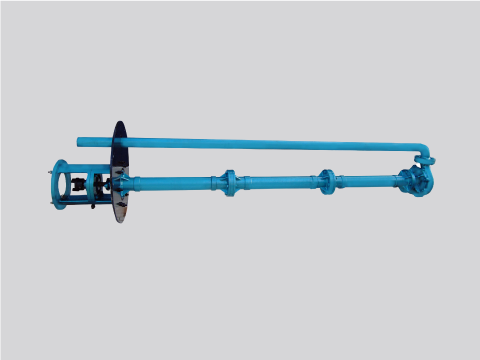

6. Vertical Submerged Process Pump

A vertical submerged process pump is designed for use in tanks or sumps, with its motor positioned above and the impeller submerged in the liquid. This design allows it to handle corrosive, abrasive, or viscous fluids efficiently, making it ideal for chemical processing and water treatment. Its compact vertical configuration helps prevent cavitation and minimizes space requirements.

Features

- High Head Per Stage

- High Capacity

- Low Maintenance

- Robust Design

- Highly Reliable

- Long Life

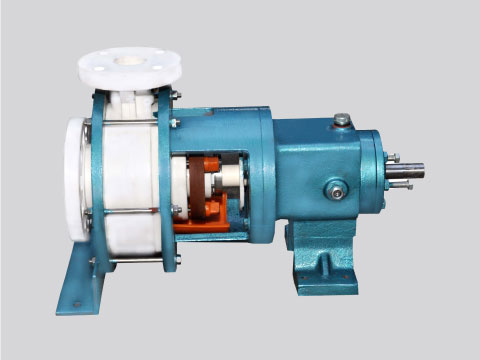

7. Polypropylene Pump

A polypropylene pump is a type of pump constructed from polypropylene, a durable and chemical-resistant thermoplastic. This material makes the pump suitable for handling corrosive or abrasive fluids, including acids, bases, and various chemicals. Polypropylene pumps are commonly used in chemical processing, water treatment, and industrial applications where resistance to chemical attack and long-term durability are essential.

Features

- Easy Maintenance

- Strong Construction

- Leak Proof

- Efficient Design

- Corrosion Resistant

8. Air-Operated Double Diaphragm Pump

An air-operated double diaphragm (AODD) pump uses compressed air to drive two diaphragms, which alternately pump fluid through the system. This pump is known for its versatility, as it can handle a wide range of fluids, including abrasive, viscous, and corrosive substances. The AODD pump is self-priming and can run dry without damage, making it ideal for various industrial applications such as chemical transfer, wastewater management, and food processing.

Features

- Easy Installation & Operation

- No Lubrication Required

- Low Maintenance

- Corrosion Resistance

- Leakproof Design

- Extremely Portable

Why Trust Jay Khodiyar Engineering for Industrial Pumps?

Jay Khodiyar Engineering has earned a reputation as a trusted industrial pumps manufacturer in the USA through its extensive expertise and commitment to quality. With years of experience, we ensure that each pump meets specific industry standards and operational requirements.

Following a stringent quality control process, we offer pumps that are highly reliable, durable, and efficient. Make a dependable choice for various industrial pump needs.